Unleash the Full Potential of Your Strawberries:

Introducing our IQF Strawberry Processing Line:

Are you ready to transform your strawberry harvest into a year-round, premium product? Our state-of-the-art line is meticulously designed to preserve the delicate flavor and vibrant color of your strawberries while maximizing efficiency.

Imagine a process where every berry is handled with care, from the moment it arrives to the instant it's frozen. Our comprehensive system ensures gentle treatment, thorough cleaning, and optimal sorting, resulting in strawberries that stand out from the crowd.

Let us be your partner in elevating your strawberry production. With a capacity of 5 tons per hour, our line is ready to handle your growing business needs.

Strawberry Processing Steps

• Receiving and Initial washing

Gentle cleansing and preparation:

Our IQF Strawberry Processing Line begins with a crucial foundation: thorough cleaning.

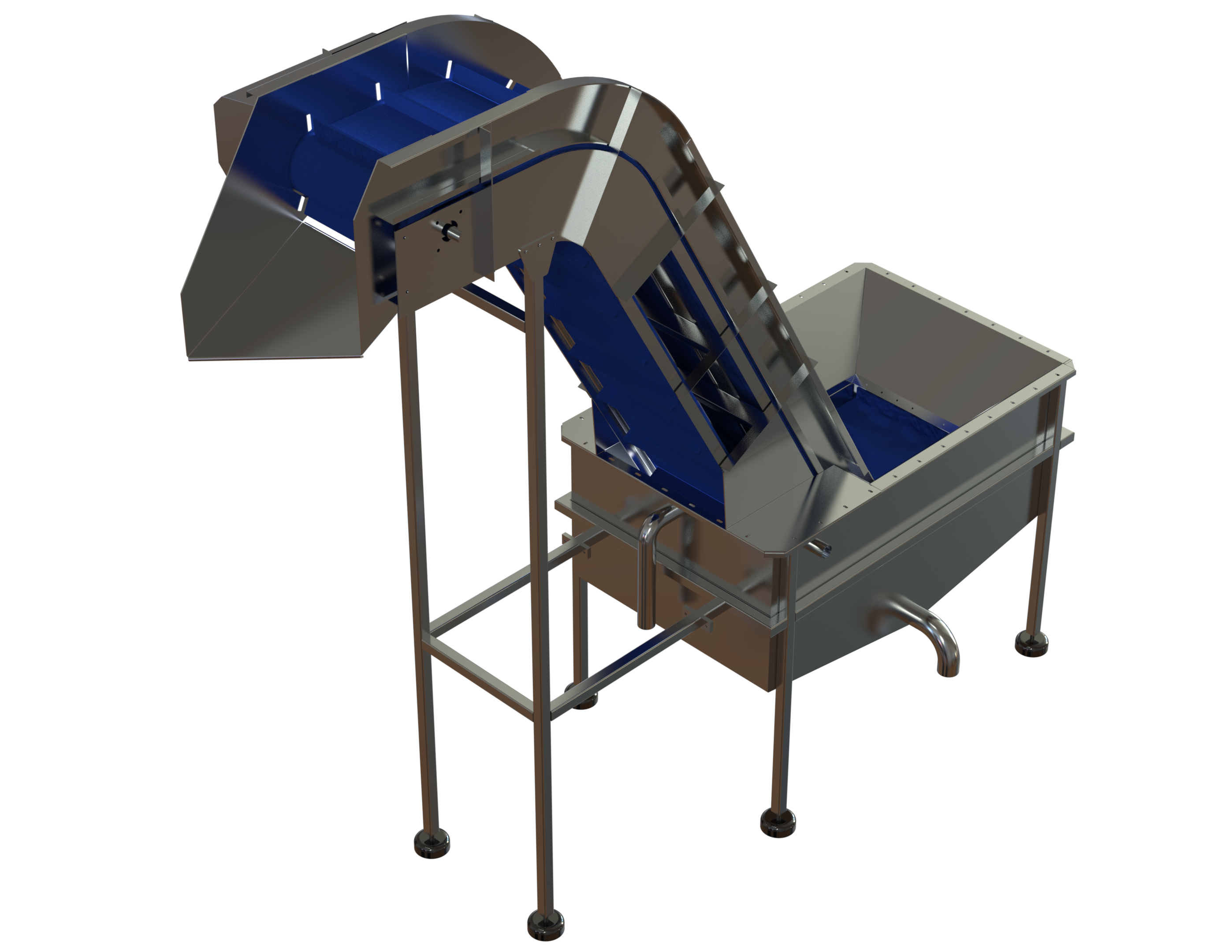

Initial Immersion and Cleansing:

Strawberries embark on their journey by entering our specialized washing Tank. Here, they undergo a gentle soaking and rinsing process, effectively removing leaves, dirt, and other impurities. Our inclined modular belt conveyor then gently lifts the refreshed berries to the next stage.

Maintaining Peak Performance:

We understand that water quality is paramount. Our system features precise water level control, allowing our production engineers to maintain optimal conditions. By regulating water flow through feed and drain valves, we ensure consistent efficiency and product quality throughout the process.

This initial step is essential in preserving the natural integrity of your strawberries, setting the stage for the exceptional end product you deserve.

• Washing

Deep Wash Technology:

After the initial cleansing, your strawberries undergo a rigorous deep wash in our advanced Air Bubble Washing Machines. This cutting-edge equipment harnesses the power of air bubbles, surging water, lifting, and spraying to achieve unparalleled cleanliness.

Key Benefits of Our Deep Wash System:

• Exceptional Hygiene: Our dual-machine setup ensures that every strawberry is thoroughly cleansed, removing even the most stubborn contaminants.

• Environmental Responsibility: By recycling filtered rinse water, we minimize water consumption and reduce our environmental impact.

• Operational Efficiency: Our self-contained lifting mechanism and easy connections streamline the process, maximizing productivity.

• Reliability and Durability: Engineered for consistent performance, our machines deliver dependable results day after day.

This critical stage guarantees that your strawberries are impeccably clean, setting the stage for the subsequent processing steps.

• Sorting

Precision Sorting:

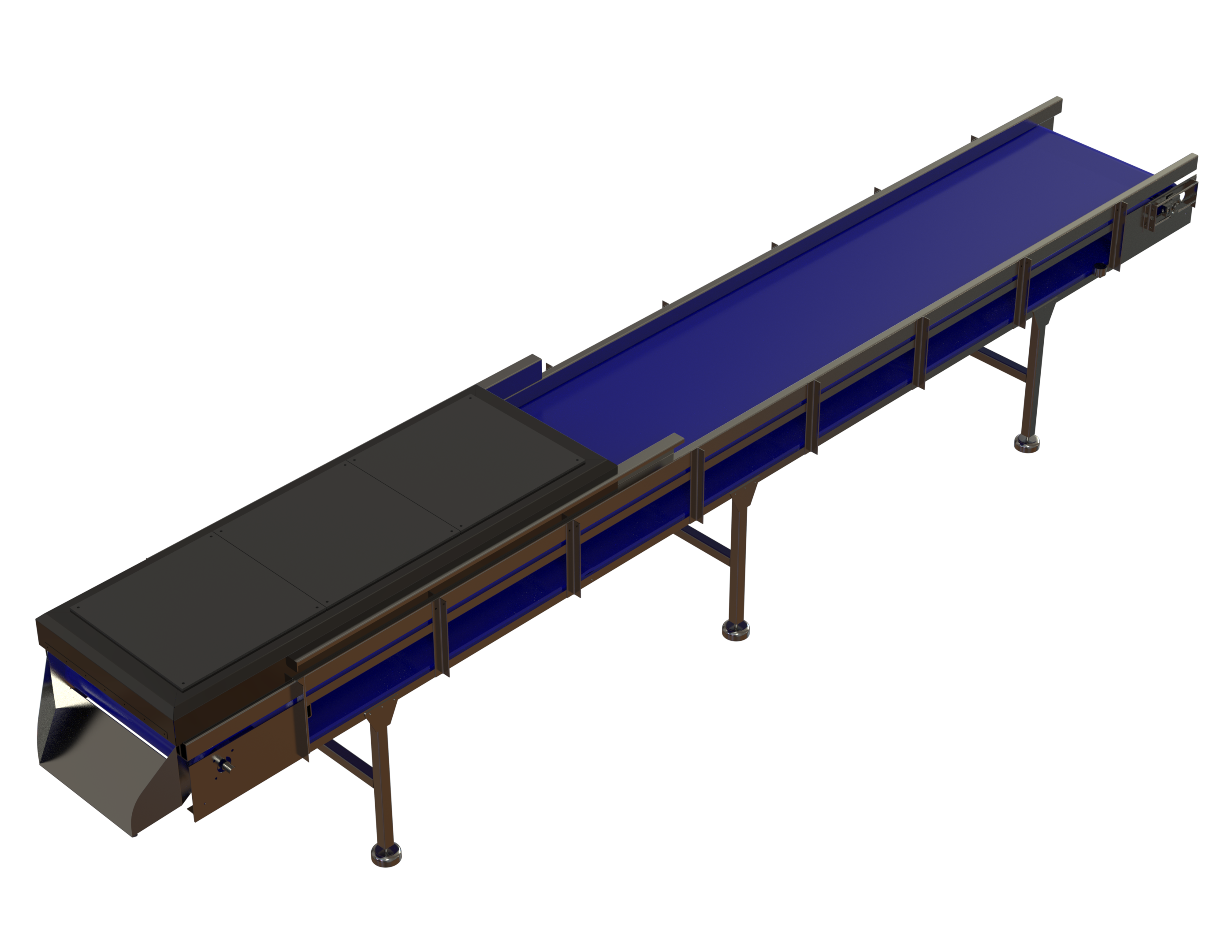

Handpicking Perfection: Following the deep cleaning process, your strawberries undergo a meticulous handpicking phase on our modular belt conveyor. This crucial step ensures that only the highest quality berries move forward.

Our dedicated sorting area, spanning four meters, provides ample space for the experienced workers to carefully inspect each strawberry. By manually removing any remaining impurities, damaged fruit, or undersized berries, we maintain the exceptional quality standards that define our processing line.

This hands-on approach guarantees that only the finest strawberries progress to the next stage, where they will be transformed into a premium end product.

• Drying

Drying for Optimal Freezing:

To ensure the highest quality frozen strawberries, proper preparation is essential. Our next step involves a crucial drying process. Utilizing powerful air blowers, we gently remove residual water droplets from each berry. This meticulous step is vital in preventing the formation of damaging ice crystals during the freezing process.

By eliminating moisture, we safeguard the delicate flavor, texture, and overall integrity of your strawberries. This careful attention to detail sets the stage for a superior frozen product.

• IQF

Lock in Nature's Sweetness: The IQF Magic:

The pinnacle of our strawberry preservation process is the IQF (Individually Quick Frozen) stage. This revolutionary technology is the key to safeguarding the strawberries' vibrant flavor, color, and texture. Unlike conventional freezing methods, our IQF system gently carries and freezes each berry individually, preventing them from clumping together. This rapid freezing process effectively locks out ice crystals, ensuring that your strawberries retain their fresh-picked taste and appearance long after harvest.

• Grading & Packing

Maximize Value: Grading and Packing for Success:

Our commitment to detail extends beyond the freezing stage. The final step in our IQF Strawberry Processing Line showcases our dedication to maximizing the value of your product.

Precise Grading for Diverse Needs:

Each strawberry embarks on a final journey through our sophisticated grading system. Here, they are meticulously sorted into three distinct categories:

• Size 1 (below 25mm): Perfect for delicate applications like garnishes and desserts.

• Size 2 (25-35mm): Ideal for baking, blending, and a variety of culinary uses.

• Size 3 (Above 35mm): Perfect for showcasing whole berries in premium presentations. This meticulous sorting ensures that every strawberry finds its ideal purpose, maximizing your product's potential.

Streamlined Packing for Efficiency:

Following grading, each size category seamlessly flows towards dedicated packing stations. This streamlined process optimizes efficiency and ensures that your strawberries are consistently presented in optimal condition.

Optional Glazing for Enhanced Appeal:

If desired, we can integrate an additional glazing step before packing. This process involves a precise water application carefully adjusted according to the berry size. This targeted approach adds a light, glistening coat, enhancing the visual appeal of your strawberries without compromising their integrity.

Guaranteed Freshness Through Cold Storage:

Every grade, meticulously sorted and packed, then embarks on its final journey—directly into our state-of-the-art cold storage facility. This ensures that your strawberries remain perfectly preserved, ready to deliver exceptional quality to your customers.