5 Tons Per Hour: High-Quality Fresh Mango Sorting & Packing Line:

Sanam Company presents the fresh mango packing line, the ideal solution to boost your productivity and product quality. With a production capacity of up to 5 tons per hour, this line ensures a high-quality final product that meets the highest global quality standards.

Fresh Mango Processing Steps

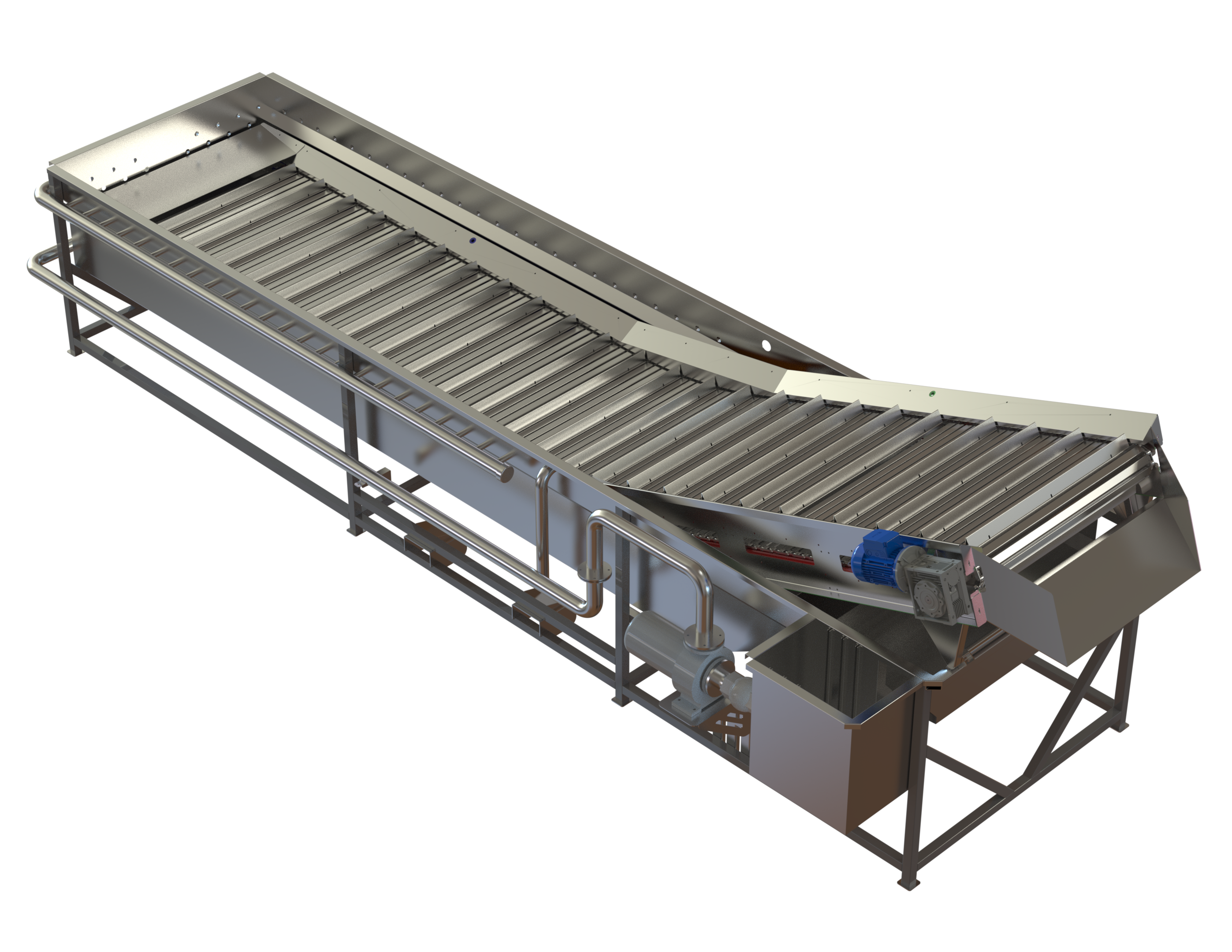

Initial Stage: Receiving and Pre-Washing

Our fresh mango processing line begins with a versatile receiving and pre-washing hopper, combining the initial infeed and pre-wash stages into one seamless operation. This innovative hopper serves as both a receiving point and a pre-wash tank, streamlining the process and maximizing efficiency. Designed for optimal performance, the hopper accommodates various feeding methods, including trailers, box tippers, and big bags, ensuring a consistent flow of mangoes. Its capacity to act as a buffer stock prevents interruptions in the processing line.

Integrated into the hopper is a perforated thermoplastic conveyor belt, which facilitates a thorough initial wash as the mangoes are received. The conveyor's adjustable speed allows for precise control over the processing rate. Constructed from durable stainless steel, the hopper is equipped with a robust cam unit and bearing housings. Powered by a reliable motor and gearbox, and controlled by an inverter for precise speed adjustment, this system ensures smooth and efficient operation. The water-filled hopper provides an effective pre-wash, gently removing dirt and debris, preparing the mangoes for subsequent stages. This combined receiving and pre-washing stage is the foundation for maintaining product quality and maximizing output.

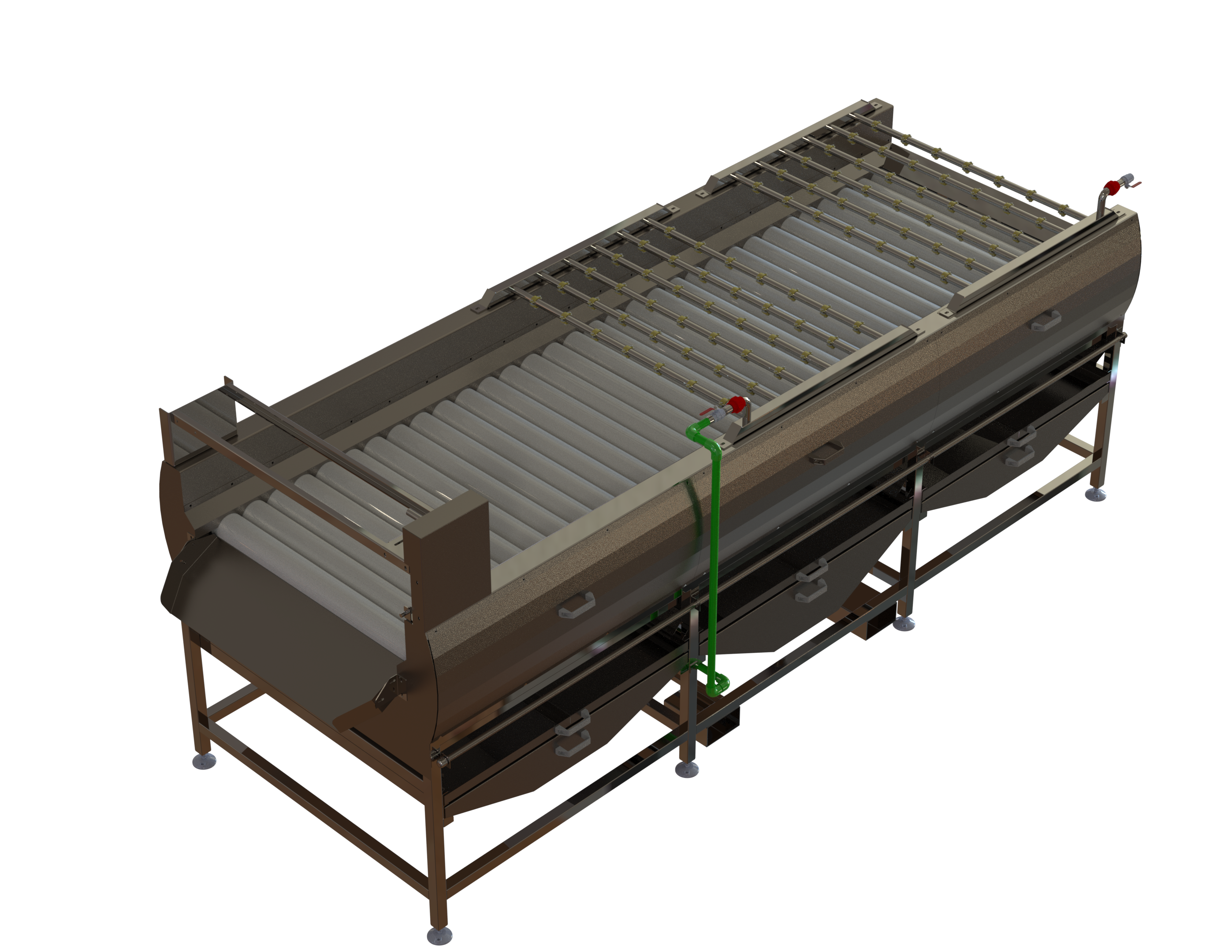

• Brushing Unit

Deep Cleaning: The Brushing Station:

Following the pre-wash, our brushing unit provides an intensive cleaning for your mangoes. Equipped with 30 rollers - a combination of brushes and sponges - this machine effectively removes stubborn dirt using high-pressure water sprays. Constructed with durable stainless-steel components, including a food-grade 304 cam unit, the brushing station ensures hygienic and efficient operation. Powered by a 2 HP gearbox motor, the machine delivers consistent performance.

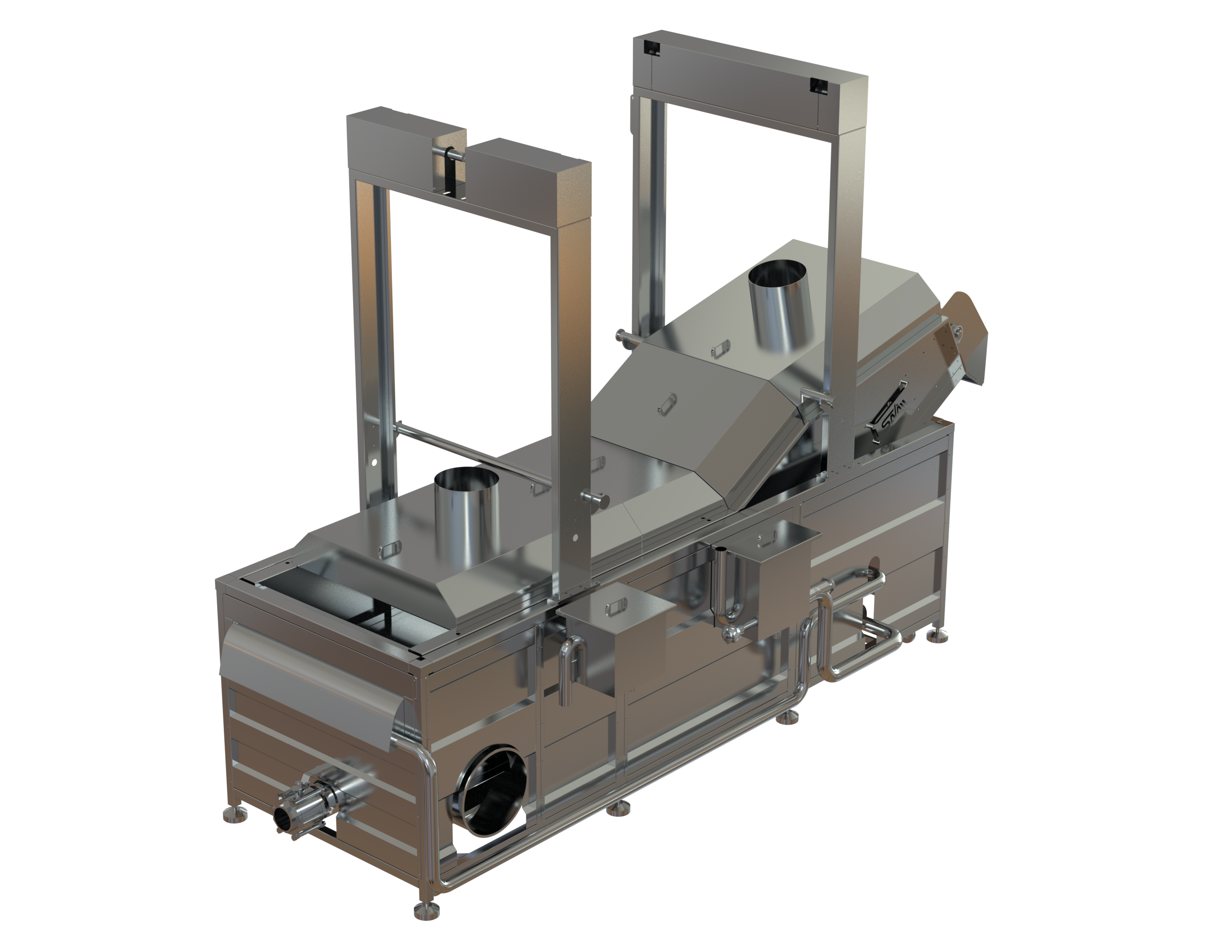

• Hot Water Treatment

Ensuring Safety and Quality:

Our hot water treatment system is designed to meet stringent international import regulations. This crucial process eliminates fruit flies and reduces decay, safeguarding both domestic and international markets. Mangos are submerged in hot water for a specified duration, depending on fruit variety and destination market requirements. The treatment tank is equipped with a heating system to maintain precise water temperature, ensuring effective disinfection. Its dimensions (1 meter wide by 7 meters long) accommodate high volumes of mangoes. The system includes an inclined modular belt for continuous product flow, seamlessly transitioning to the next processing stage. Constructed with durable stainless-steel components, the hot water treatment unit guarantees hygiene and longevity.

• Chemical Treatment

Preserving Mango Quality:

Our chemical treatment stage is designed to extend the shelf life of your mangoes and maintain their optimal quality. This process involves immersing the fruit in a carefully formulated chemical solution that inhibits decay and preserves essential attributes like firmness, sweetness, and vitamin C content. The treatment tank is specifically designed for this purpose, measuring 140 cm wide by 4 meters long. This spacious unit ensures thorough coverage of the mangoes during the treatment process. Equipped with an inclined modular belt, the system seamlessly transfers the treated fruit to the next stage of the processing line. The tank is constructed with durable stainless steel components, including a food-grade 304 cam unit, to guarantee hygiene and product safety. Powered by three robust motors, the chemical treatment system efficiently handles high volumes of mangoes while maintaining precise control over the treatment process.

• Initial Drying:

Drying Tunnel: Preparing for Waxing:

Our drying tunnel is a critical step in the mango processing line, ensuring that the fruit is thoroughly dried after the chemical treatment. This process prepares the mangoes for the subsequent waxing stage by removing excess moisture. The tunnel features a conveyor system equipped with hot air generators that gently dry the fruit as it moves through. Its design, including a 5-meter length, iron frame, and effective insulation, optimizes drying efficiency while maintaining fruit quality. The tunnel's components, such as aluminum rollers, a chimney, and a powerful gearbox motor, ensure smooth operation and durability. Equipped with an Italian-made burner and a control panel for precise temperature and speed regulation, our drying tunnel delivers consistent results.

• Waxing

Enhancing Mango Appearance and Shelf Life:

Our waxing station is a crucial component in achieving the desired finish for your mangoes. By applying a thin layer of food-grade wax, we enhance the fruit's appearance, reducing water loss and extending shelf life. This process requires a completely dry fruit surface, ensuring optimal wax adhesion. Our waxing unit features a dry brushing system equipped with specialized brushes that evenly distribute the wax over each mango. Constructed with durable materials, including galvanized steel, aluminum, and stainless steel, the machine guarantees long-lasting performance and hygienic operation. This essential step in the processing line contributes significantly to the overall quality and marketability of your mangoes.

• Primary Drying (Post-Waxing Drying)

Post-Waxing Drying Tunnel:

Final Preparation for Packing Our post-waxing drying tunnel ensures that the wax is completely set and dried before the packing process. This crucial step optimizes product presentation and prevents smudging or damage to the wax coating. The tunnel features a 7-meter conveyor system equipped with powerful hot air generators that effectively remove residual moisture from the waxed mangoes. Its robust construction, including an iron frame, insulation, and durable aluminum rollers, guarantees long-term performance. The integrated inverter motor provides precise speed control, while the Italian-made burner delivers efficient heat distribution. A user-friendly control panel allows for precise temperature and speed adjustments, ensuring optimal drying conditions. To further enhance the efficiency of the process, the tunnel incorporates a 5-meter sorter with a 140 cm roller width. This component enables initial sorting based on size or quality, streamlining the subsequent packing process. The sorter's frame, constructed from iron pipes and plastic rollers, ensures gentle handling of the mangoes. Equipped with lighting, the sorter facilitates accurate and efficient product inspection. This advanced drying and sorting combination prepares your mangoes for the final packing stage, maximizing product quality and presentation.

• Grading

Precise Size Differentiation for Optimal Packing:

Following the primary drying stage, our mango processing line includes a critical grading step. This stage focuses on precisely differentiating between the various sizes of the fruit, ensuring accurate sorting and meeting diverse market requirements. Our specialized grading machine employs a series of calibrated cups to meticulously categorize mangoes based on their individual dimensions. This process allows for clear distinction between different size categories. This distinction allows for targeted packing based on customer needs. This grading process streamlines the packing stage, enabling efficient and accurate filling of boxes and crates according to specific size requirements. By precisely differentiating between sizes, we optimize product presentation and cater to the diverse needs of our customers. This crucial grading step between drying and packing plays a vital role in delivering high-quality, market-ready mangoes.

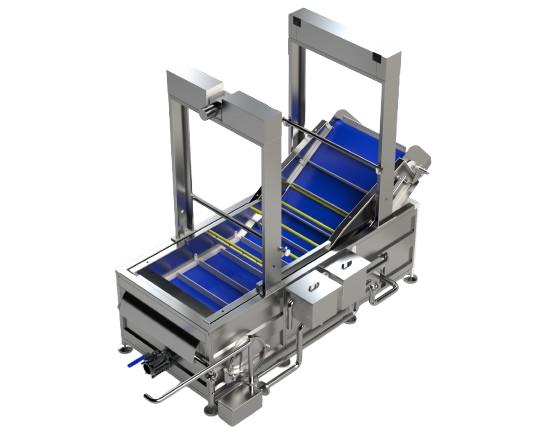

• Sorting & packing

Final Stage: Tailored Sorting and packing:

The final step in our mango processing line is the meticulous task of sorting and packaging. Our sorting and packing table is the heart of this final stage. As it’s a 5-meter long and a 140 cm wide , it provides ample space for efficient product handling. The table's robust iron frame ensure gentle treatment of the mangoes. Integrated lighting enhances visibility for precise sorting. Each package is carefully assembled based on factors such as weight, ripeness, and customer specifications. To maintain product traceability and comply with international standards, all packaging includes clear labeling with production date and other relevant information. Our commitment to flexibility and quality ensures that your mangoes are presented in the most appealing and protective manner, ready to captivate consumers.