Unlock the Full Potential of Your Sweet Potato Harvest

· One of Egypt's golden crops is ripe for the taking. Sweet potatoes, a nutritional powerhouse and global export darling, are ready to be transformed into a lucrative venture. Our state-of-the-art processing line is your key to unlocking this golden opportunity.

· Imagine transforming raw sweet potatoes into a high-value product, ready to captivate markets worldwide. Our seamless process, encompassing washing, drying, sorting, grading, and packing, is meticulously designed to elevate your sweet potato operation.

· Get ready to embark on a journey that will revolutionize your business. Discover how our processing line can be the cornerstone of your success.

Sweet Potato Processing Steps

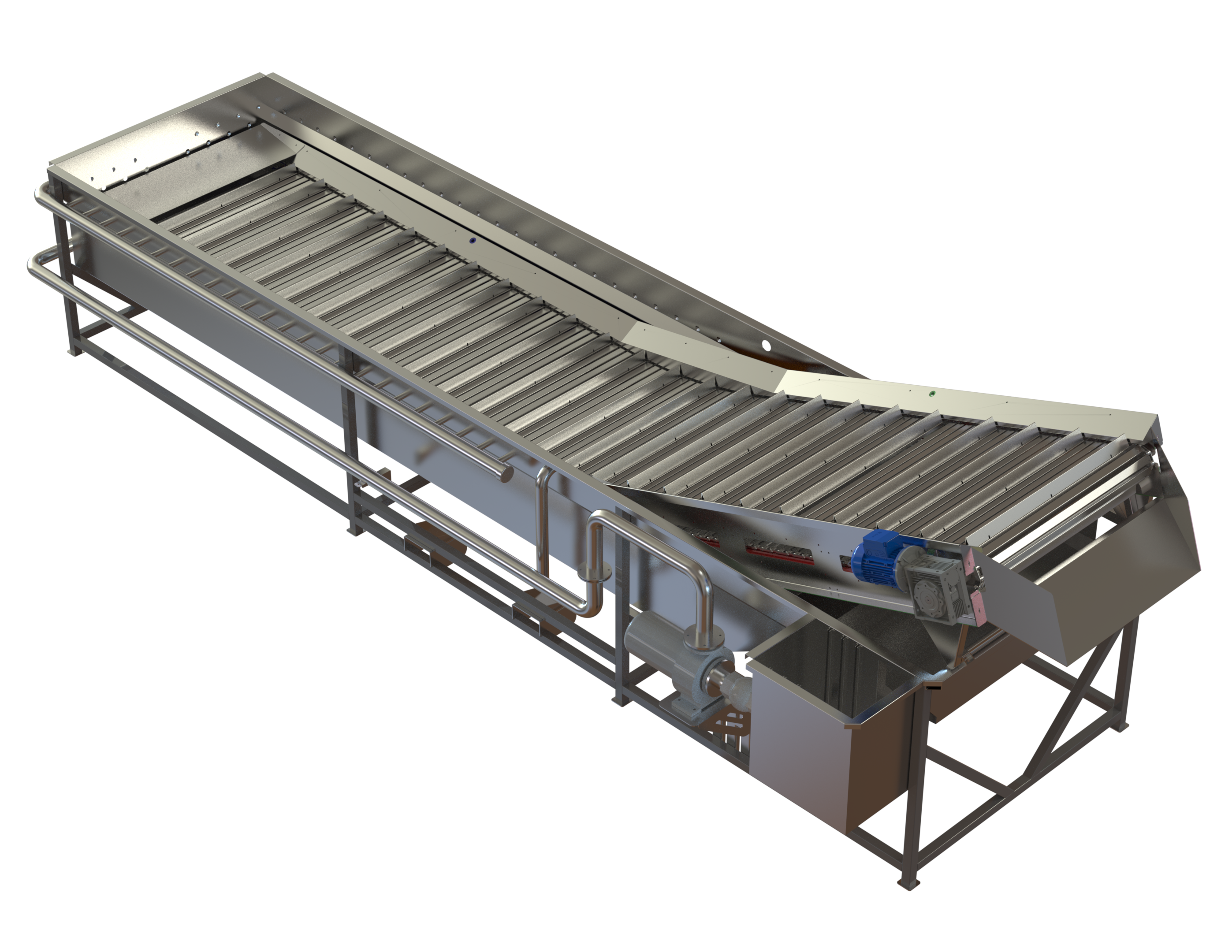

• Receiving and Initial Washing

Removing the Dirt: Our Receiving and Pre-Washing Process:

The journey of transforming raw sweet potatoes into a marketable product begins with a crucial first step: thorough washing. Our process is designed to gently yet effectively remove soil, debris, and impurities, preserving the quality of the crop. Sweet potatoes are initially received in a washing sink or wet hopper, where they undergo a deep cleansing. This stage involves a combination of soaking, agitation, and powerful air-bubbling to loosen stubborn dirt and create a Jacuzzi-like environment. This gentle yet effective method not only cleanses the sweet potatoes but also cools them down, a crucial step in post-harvest handling. Our pre-soak tanks are engineered to optimize this process. The longer dwelling time allows for more effective dirt removal, while the dump valves ensure easy cleaning of the tank. Once thoroughly cleansed, the sweet potatoes are carefully conveyed to the next stage: brush washing. This two-step approach guarantees that your sweet potatoes receive the ultimate pampering treatment. By prioritizing gentle handling and maximum cleanliness from the outset, we lay the foundation for producing high-quality sweet potato products.

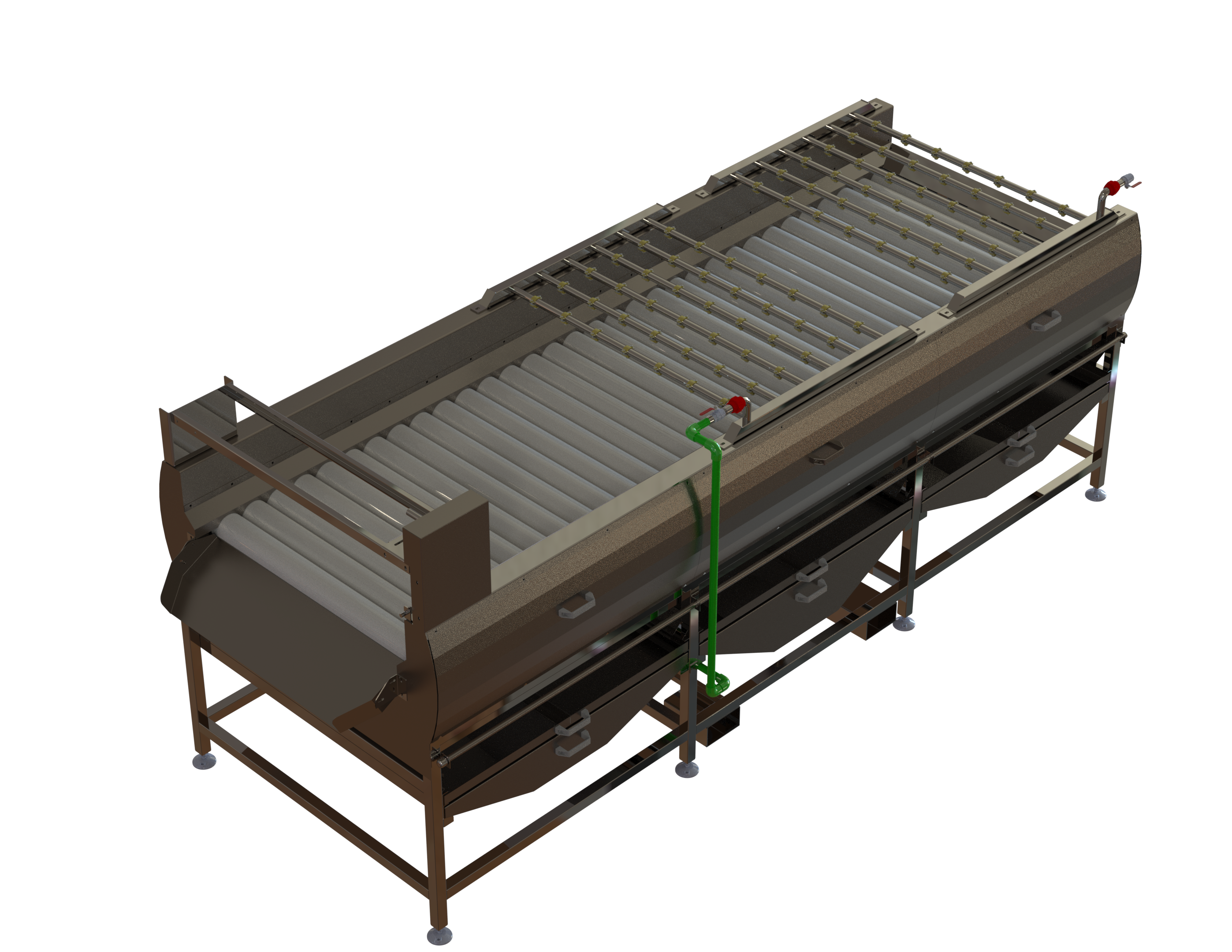

• Washing

Brush Wash: A Deep Clean for Impeccable Quality:

Once your sweet potatoes have enjoyed their initial soak, they move on to the next level of purification: our high-pressure brush wash. This stage is crucial in eliminating any residual dirt, mud, or impurities that may remain. Our advanced washing machine features a bed of rotating brushes that gently yet vigorously scrub each sweet potato. Simultaneously, high-pressure water jets target every surface, ensuring a thorough and deep clean. This powerful combination effectively removes stubborn dirt, preparing the sweet potatoes for the subsequent stages of processing. We understand that cleanliness is paramount in food production. Our brush wash system is meticulously designed and maintained to meet the highest hygiene standards.

• Drying

Drying: Perfecting the Product:

After their invigorating bath, the sweet potatoes enter the drying phase. This critical step is essential to prepare the produce for the subsequent stages of processing. Our state-of-the-art drying tunnel is designed to efficiently remove excess moisture from the sweet potatoes. As the tubers move along the roller conveyor, they are exposed to a carefully controlled flow of warm air generated by our advanced heating system. This process ensures even drying, preventing any potential issues with product quality. By thoroughly drying the sweet potatoes, we create an ideal environment for the next stages of sorting, grading, and packing. This step is crucial in maintaining the product's freshness, taste, and overall shelf life.

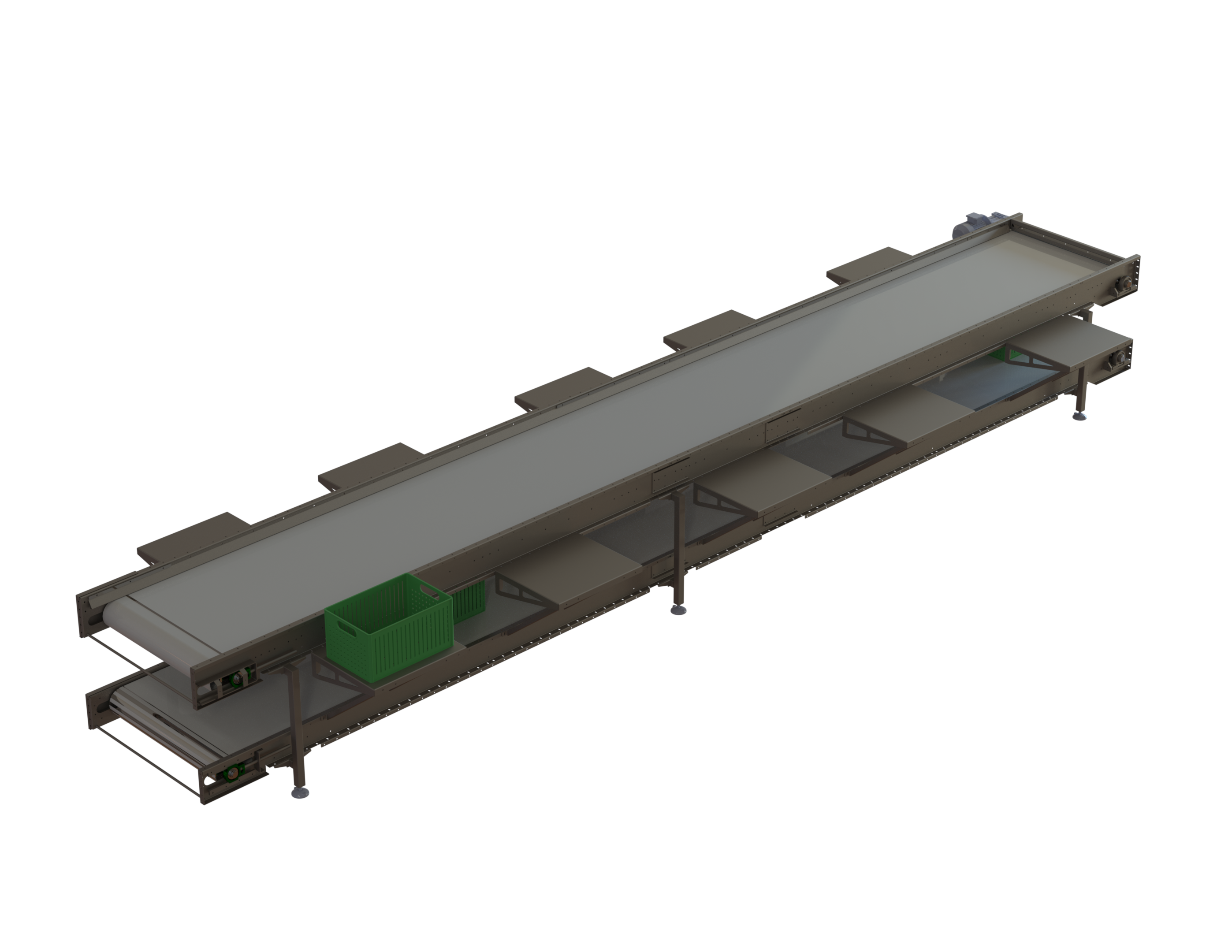

• Sorting & Grading

Sorting and Grading: Precision and Quality Assurance:

Ensuring product consistency and quality is paramount. Our sorting and grading stage is meticulously designed to achieve this. The process begins with a manual inspection station where skilled workers carefully examine each sweet potato. Damaged, undersized, or substandard tubers are removed from the production line, guaranteeing only the finest quality products move forward. Following this initial inspection, the sweet potatoes are conveyed to a grading station. Here, our team expertly categorizes the remaining produce into different grades based on factors such as size, shape, and color. This precise sorting ensures that our customers receive products that meet their exact specifications. With our dedicated sorting and grading process, we deliver sweet potatoes that not only meet but exceed industry standards.

• Packing

Packaging: The Finishing Touch:

The final stage in our sweet potato processing line is packaging. After undergoing rigorous cleaning, drying, grading and sorting, the premium-quality sweet potatoes are carefully packed to preserve their quality and ensure safe transportation. The packaging process involves carefully placing the graded sweet potatoes into sturdy boxes or crates. These containers are designed to protect the product during transportation and storage, ensuring that it reaches your customers in pristine condition.