Elevate Your French Fries Production

Discover the future of French fries production with our cutting-edge 3-ton per hour line.

· Crafted to perfection, our tailored solutions deliver unparalleled quality and reliability.

· As Egypt's leading provider, we offer comprehensive lines designed to transform ordinary potatoes into extraordinary fries.

· From initial processing to final packaging, our state-of-the-art equipment ensures consistent results and maximum efficiency.

French Fries Production Line Steps:

• Material Feeding:

1. Receiving Hopper:

Our production process begins with the receiving hopper, the crucial first step in transforming raw potatoes into delicious French fries. This essential component efficiently collects incoming potatoes, ensuring a steady supply for the production line. Designed with a capacity of 8 tons per hour, the hopper is constructed from durable, electrostatic painted steel for long-lasting performance. By seamlessly transferring potatoes from storage bags to the grading station, it sets the stage for the entire production process.

.png)

2. Mono grader:

Following the initial collection of potatoes, our mono grader ensures optimal product quality. This specialized machine accurately sorts potatoes by size using a unique roller system. By effectively removing dust and stones up to 26mm in diameter, the grader prepares the potatoes for the next stage of processing. The mono grader efficiently handles large volumes while maintaining precision. Its durable steel construction and waste removal conveyor contribute to smooth operations and a clean work environment.

%202.png)

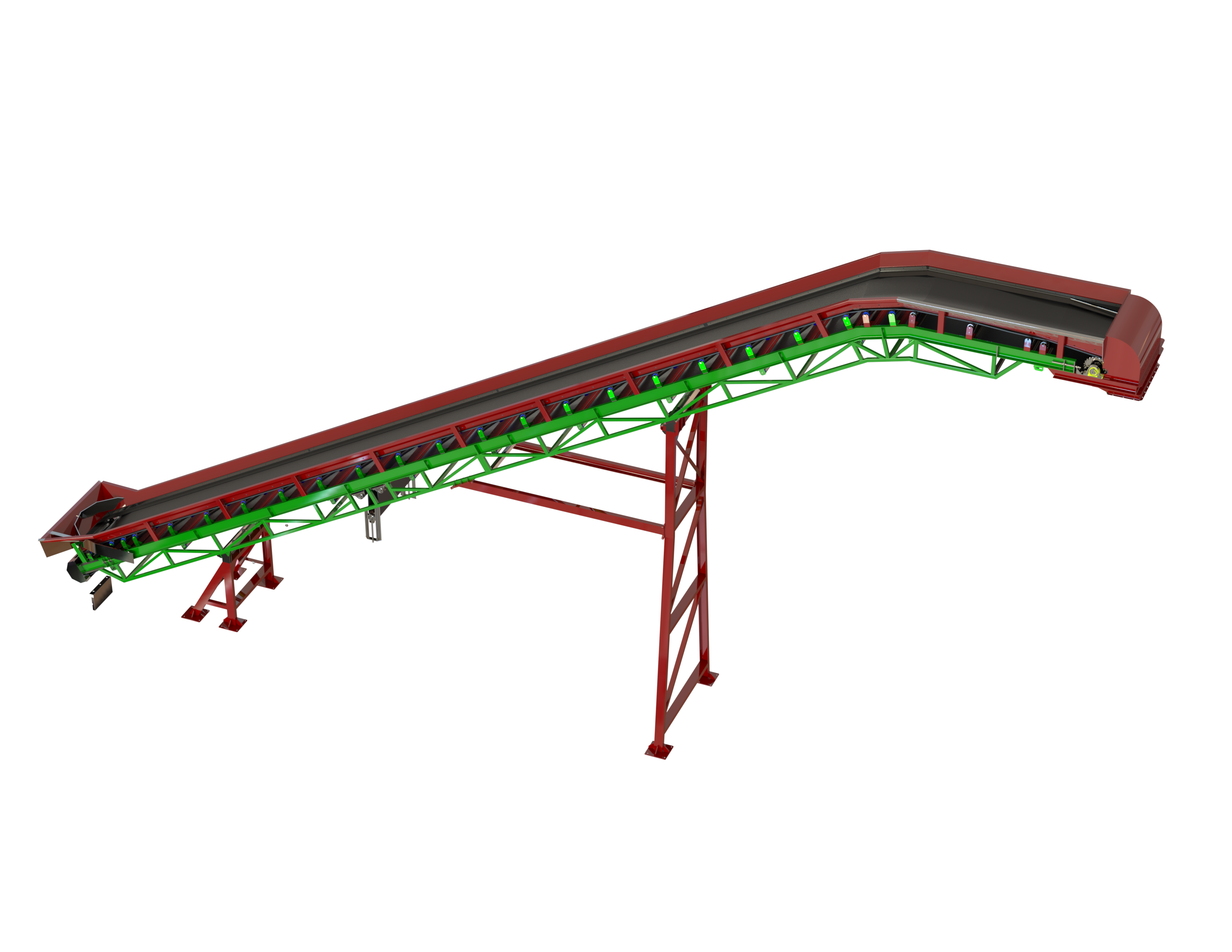

3. The Chevron Elevate Pro Conveyor:

Our production process relies on efficient material handling, and the Chevron Elevate Pro Conveyor plays a vital role. Designed for inclined transportation, this specialized conveyor utilizes a unique chevron-shaped belt to ensure secure and reliable movement of potatoes. The belt's superior grip prevents slippage, optimizing overall efficiency and productivity in delivering potato to bankers buffering station.

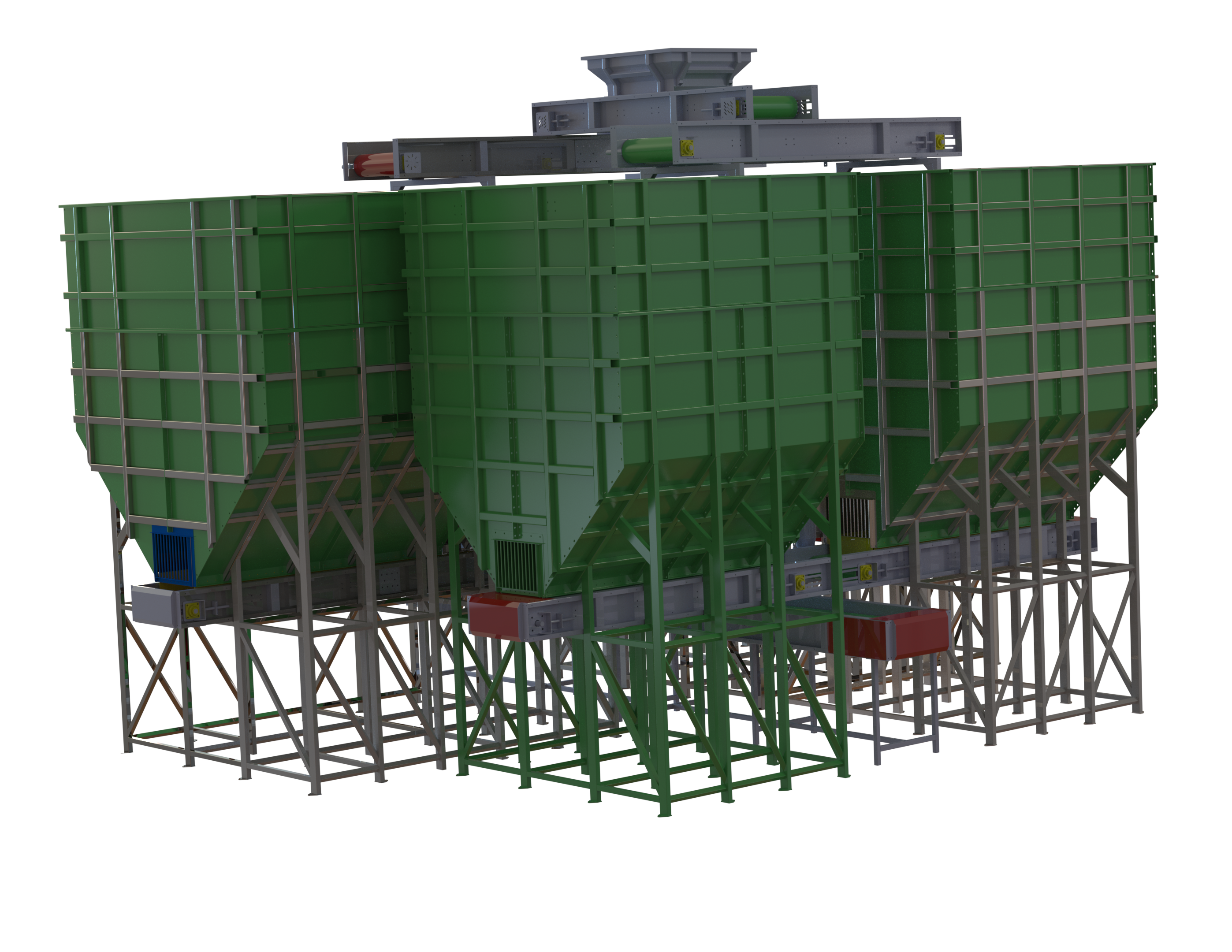

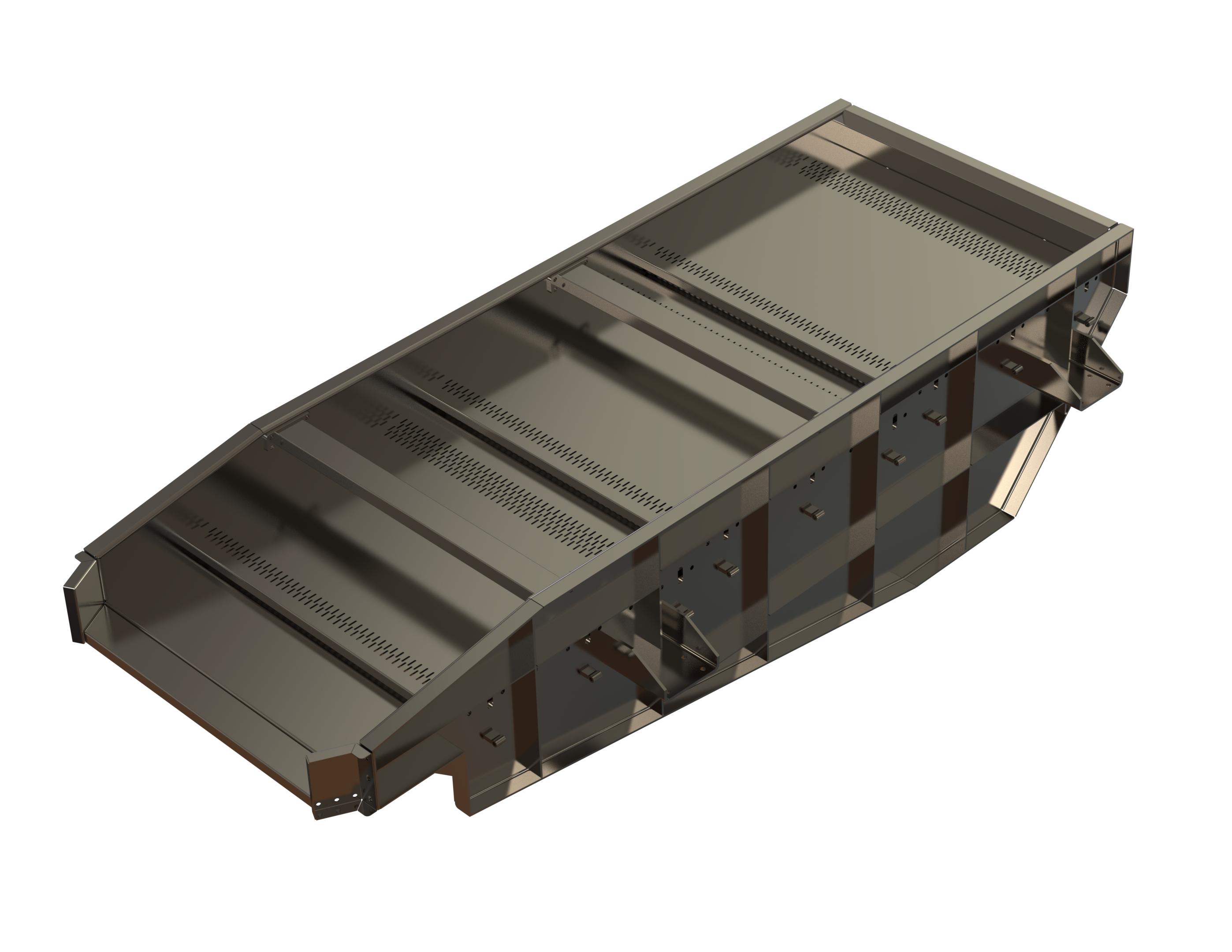

4. Bankers Distribution System:

Our production line incorporates a banker distribution unit to ensure potatoes are evenly distributed for optimal processing. This system features three conveyors feeding into four bankers, providing flexibility in managing product flow. The unit utilizes three lite belt conveyors and a receiving hopper for efficient material handling. This strategic distribution enhances overall productivity and streamlines the production process.

• Pre-Cleaning:

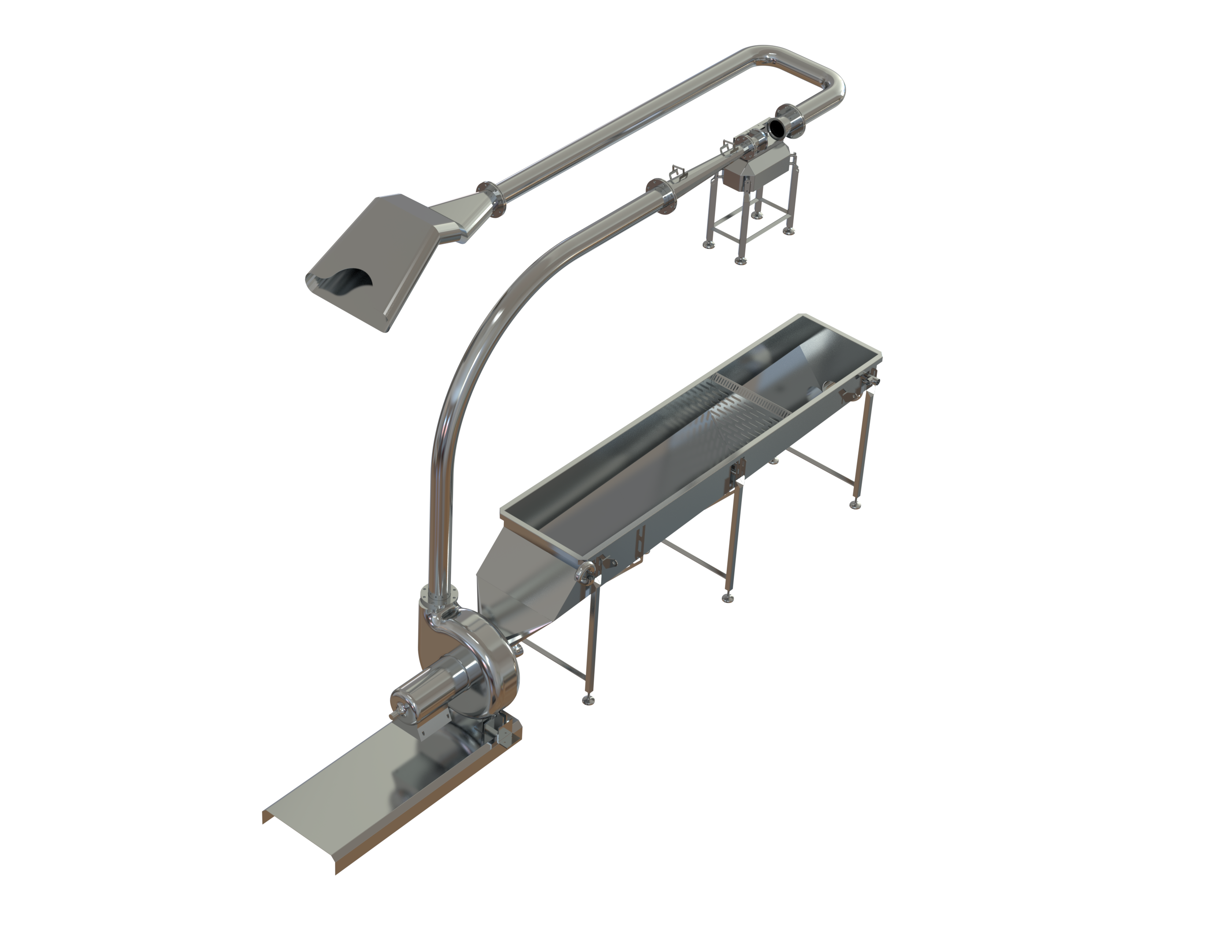

Removing Obstacles: The Cyclone Destoner:

Before transforming potatoes into the crispy delights you crave, we begin by removing unwanted elements. Our cyclone destoner is the first step in ensuring only the purest potatoes enter our production process. Utilizing water flow and centrifugal force, this machine effectively separates potatoes from stones and clay clumps. Its robust stainless-steel construction and durable polyurethane lining guarantee optimal performance and longevity. By carefully adjusting gradient and flow rates, we achieve maximum efficiency in removing impurities.

• Washing:

Potato Washing: The First Step to Flavor:

Our potato washing process is designed to deliver the purest potatoes for your perfect fries. Utilizing a drum washer, we gently yet effectively remove soil, clay, and sand. This essential step is the foundation for producing high-quality French fries. Our drum washer employs a unique design featuring alternating steel strips with smooth edges. This innovative approach ensures that potatoes are cleaned thoroughly without any damage. The machine's open design allows for easy maintenance and cleaning, while also optimizing water usage. By prioritizing cleanliness from the outset, we guarantee that only the finest potatoes make it to the next stage of the French fry production process.

• Peeling:

1. Steam peeling:

Once our potatoes are free from impurities, they undergo a precise transformation. Our steam peeling machine removes only the skin, preserving the potato's natural integrity. This innovative technology ensures maximum yield while minimizing waste. Equipped with an exceptionally thin blade, our machine delivers fast, accurate, and reliable peeling results. By utilizing steam, we guarantee a gentle yet efficient process that leaves the potato's core intact. This crucial step is essential for producing French fries with exceptional taste and texture.

2.Dry Brushing:

Perfecting the Peel: The Dry Brushing Process:

Following the steaming process, our potatoes undergo a meticulous dry brushing treatment. This crucial step removes any remaining peel residue, ensuring a flawless finish. Our machine features rotating brushes designed to gently yet effectively clean the potato's surface without damaging its shape. Built with durability in mind, our dry brush machine employs a robust gear-drive system that guarantees smooth, vibration-free operation. This advanced technology minimizes wear and tear, extending the machine's lifespan and reducing maintenance requirements. By prioritizing efficiency and precision, we deliver perfectly prepared potatoes ready for the next stage of production.

• Cutting:

1. Potato size Grader:

Optimal French fry production begins with precise potato sizing. Our potato size grader ensures smooth processing by accurately sorting potatoes based on size. By preventing larger potatoes from entering the hydro cutter, we eliminate potential blockages and maintain consistent product quality. This essential machine directs oversized potatoes to a mechanical cutter for appropriate processing, optimizing overall efficiency.

2. The cutting process:

Precision Cutting: Transforming Potatoes into Perfection:

The heart of our French fry production process is our cutting machine. This state-of-the-art equipment transforms peeled potatoes into perfectly uniform fries, wedges, or slices. Designed for easy operation, our machine offers unparalleled versatility and precision. The interchangeable knife block system allows for quick and effortless adjustments, ensuring consistent product quality. Our machine is built with efficiency in mind, minimizing blockages and eliminating the need for additional tools. By incorporating stainless steel pumps and reducing mechanical components, we've optimized maintenance and water consumption. The result is a machine that delivers exceptional performance, producing consistently delicious French fries while maximizing resource efficiency.

• Sliver Removal:

Our post-cutting sliver remover meticulously eliminates tiny fragments and slivers produced during the cutting process. This essential step safeguards product purity, ensuring a superior final product free from contaminants. Our machine's stainless-steel construction guarantees durability and hygiene, while adjustable rollers optimize the removal process for precise results.

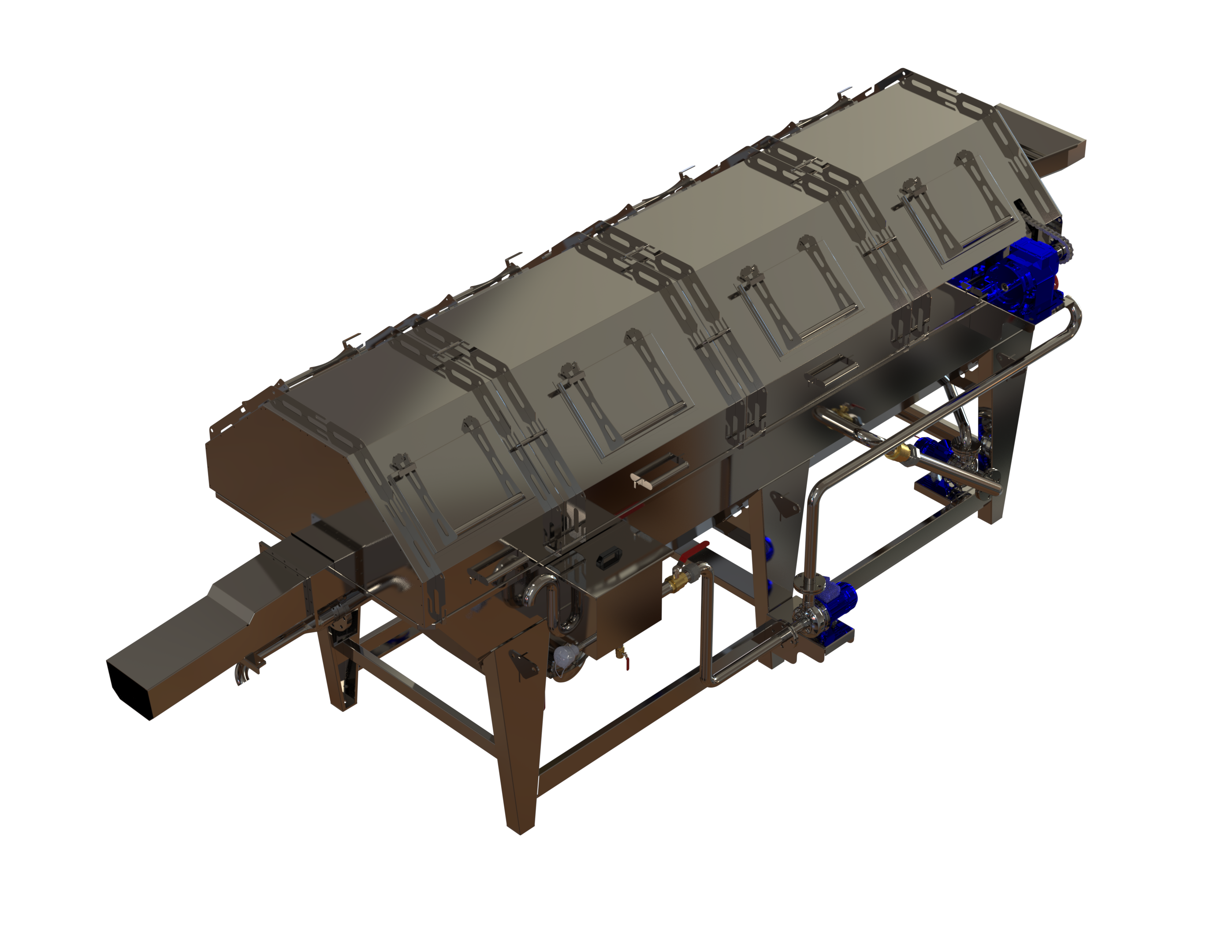

• Blanching:

A crucial step in creating exceptional French fries is blanching. Our screw-type blancher gently cooks potato strips by immersing them in hot water. This process significantly enhances the efficiency of subsequent steps, while also influencing the final product's crispness, shelf life, color, and firmness. By precisely controlling blanching time and temperature, we optimize the potato's texture and flavor. Our robust and low-maintenance blancher, combined with powerful pump systems, ensures even heat distribution and product flow for consistent results.

• De-watering:

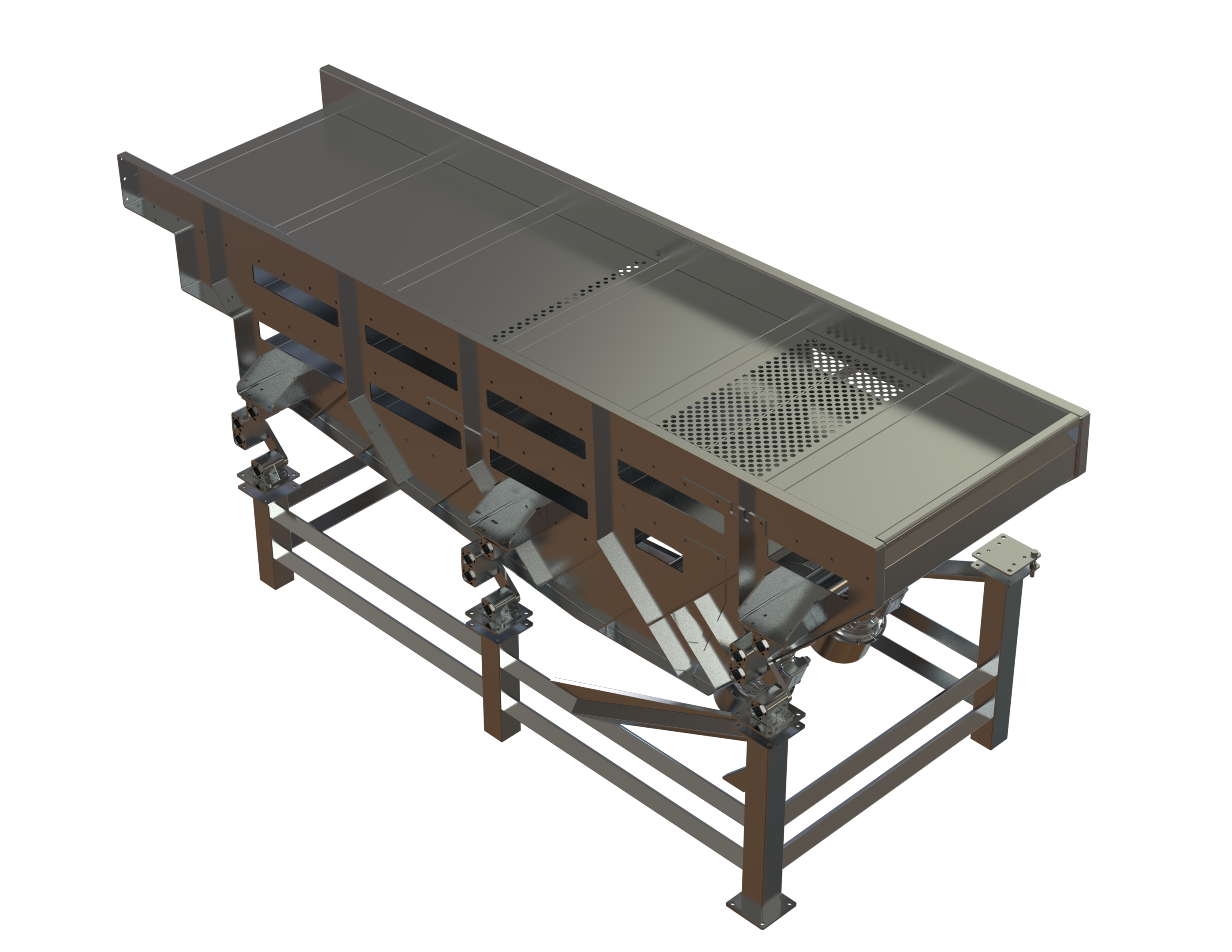

Efficient Dewatering: The Vibrating Separator:

Our production process incorporates a dewatering vibrator to optimize efficiency. This specialized equipment effectively removes excess water from the product through vibration. Powered by oscillation suspensions, the vibrator generates consistent and reliable vibrations, ensuring thorough water removal. This crucial step prepares the product for subsequent processing stages.

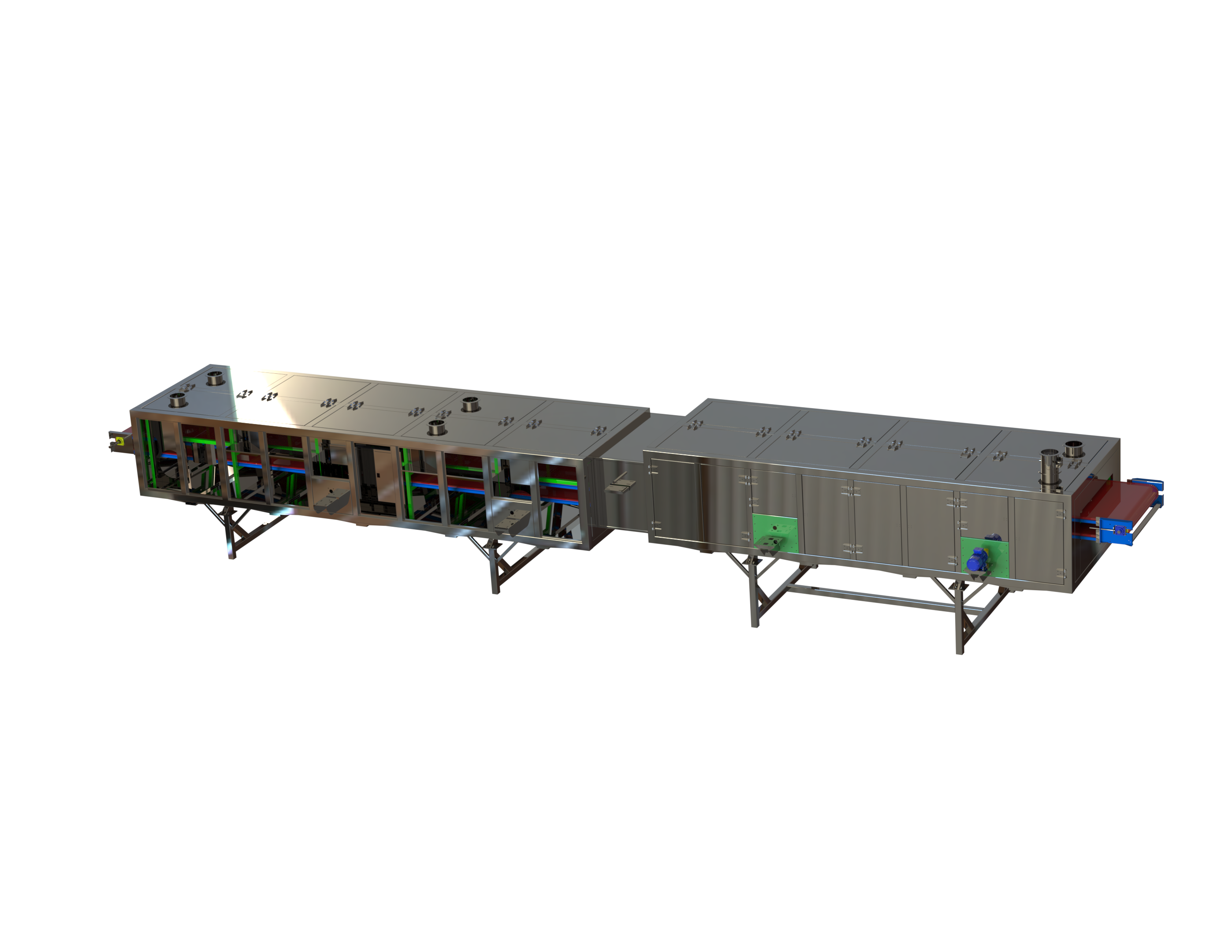

• Drying:

Our French fry dryer is essential for producing exceptional fries. By effectively removing excess moisture from blanched potatoes, we enhance the final product's crispness, texture, and shelf life. Our belt dryer utilizes heated air to gently dry the potatoes in a controlled environment. This precise drying process ensures consistent product quality and prepares the fries for the frying stage.

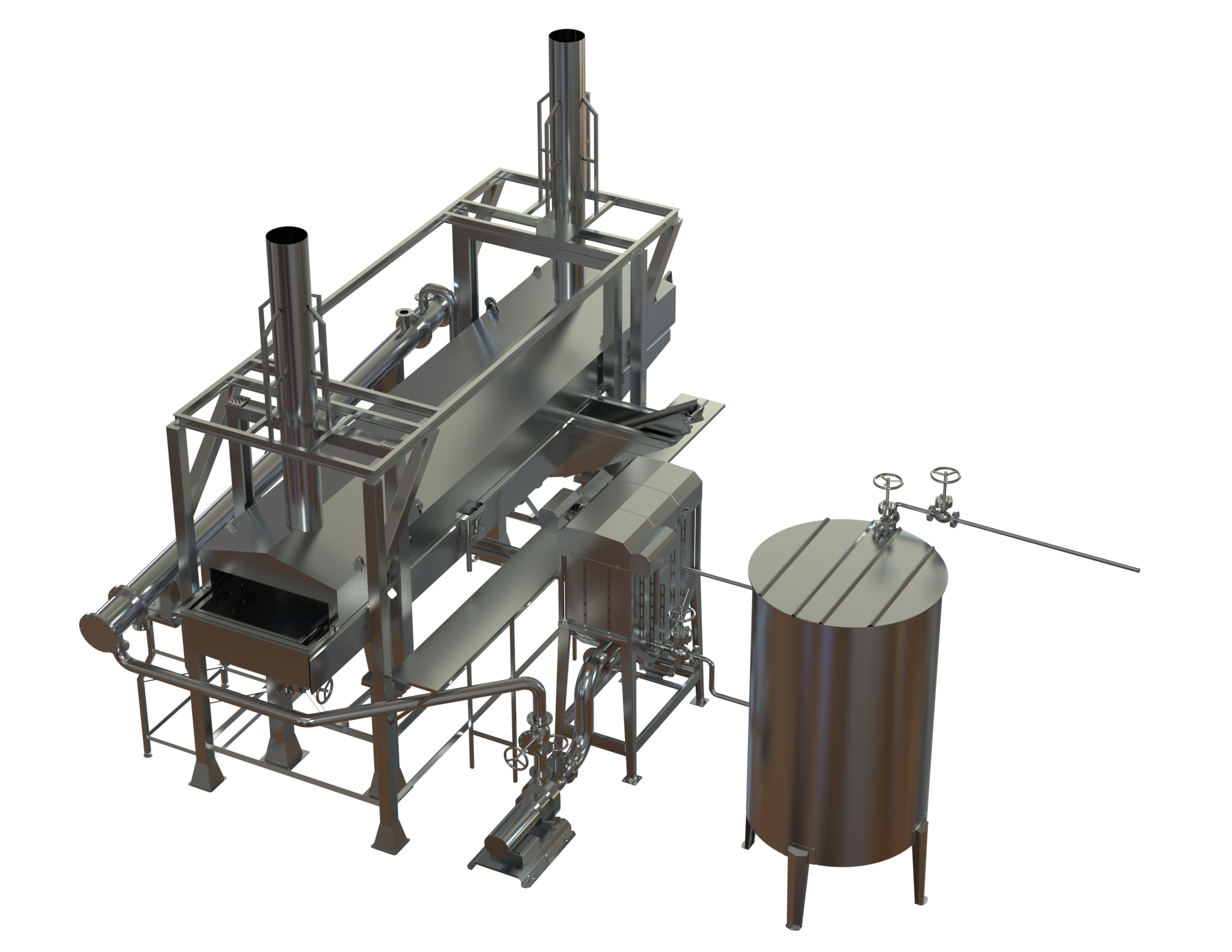

• Frying:

Frying as The Final Touch:

Our advanced frying system delivers consistently perfect French fries while prioritizing sustainability. Equipped with a high-efficiency heating system and precise temperature control, we achieve optimal results. The machine's large capacity ensures efficient production without compromising quality. Designed with the environment in mind, our fryer reduces oil consumption and minimizes its footprint. Its hygienic design and low-maintenance components make it easy to operate and clean. By combining cutting-edge technology with a commitment to sustainability, we offer a frying solution that delivers exceptional results.

• De-oiling:

Optimal Oil Reduction: The Defatting Vibrator:

To achieve the perfect balance of flavor and health, our production process incorporates a defatting vibrator. This specialized equipment effectively removes excess oil from freshly fried potatoes, enhancing the product's taste and texture. Utilizing oscillation suspensions, the vibrator generates precise vibrations to separate oil from the fries. Equipped with an oil collection drain, the machine ensures efficient oil recovery and recycling.

• Pre-cooling:

Pre-Cooling: Preserving Freshness:

To maintain optimal product quality, our production line incorporates a pre-cooling stage. This critical step rapidly reduces potato temperature before freezing. Our three-layer conveyor system and cooled air circulation ensure efficient and even cooling, preserving the potatoes' freshness, flavor and texture.

• IQF:

Lock in Freshness: The Crucial IQF Stage:

The heart of our production process is the IQF (Individually Quick Frozen) stage. This critical step is paramount in preserving the exceptional quality of our French fries. Unlike traditional methods, our IQF technology eliminates the need for mechanical components, gently carrying and separating each fry individually as it freezes. This rapid freezing process prevents the formation of damaging ice crystals, safeguarding the fries' original texture, flavor, and appearance.

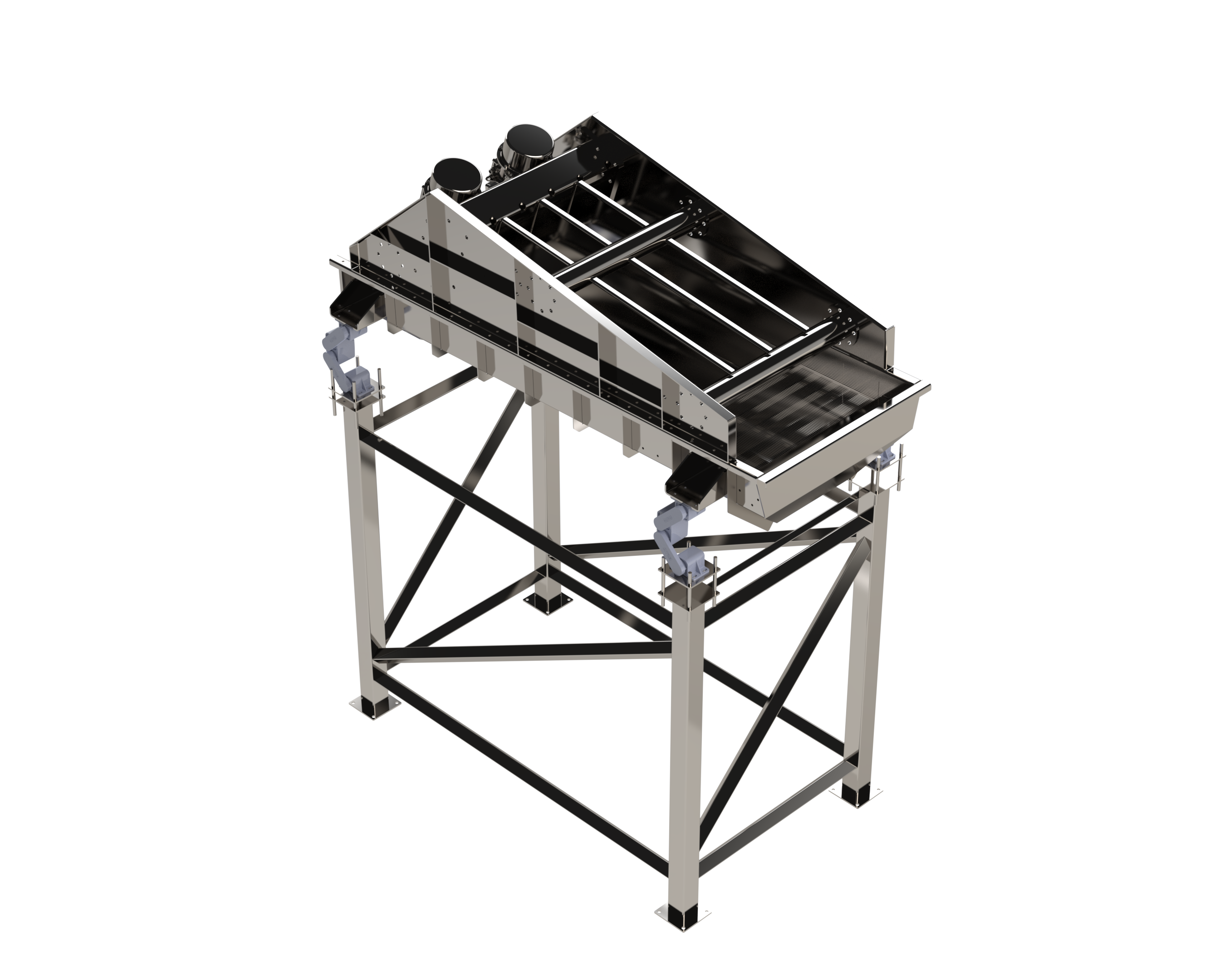

• Length grading:

Achieving Uniformity: The Length Grader:

To ensure consistent product quality, our French fries undergo a precise sizing process. Our length grader accurately sorts fries into specific lengths based on desired product specifications. The machine features interchangeable sieves for precise sorting, allowing for one, two, or three layers of different lengths. Advanced vibration technology, powered by unbalance motors, gently transports and separates the fries according to size. This crucial step guarantees uniform and visually appealing French fries.

• Packing & Storing:

The final stage in our production process is dedicated to preserving the exceptional quality of our French fries. Our advanced packaging system carefully seals each portion, protecting the fries from external contaminants and maintaining their freshness. The packaging is designed to optimize product visibility and appeal, while clear labeling provides essential product information. To ensure long-lasting quality, our storage facilities maintain precise temperature and humidity levels. This controlled environment safeguards the fries' texture, flavor, and overall integrity, guaranteeing a consistently delicious product for consumers.