Introduction to Our Sugarcane Seedling Production Line

Revolutionizing Sugarcane Cultivation in Egypt

At Sanam, we are proud to offer a comprehensive sugarcane seedling production line that is setting new standards in Egyptian agriculture. Our cutting-edge technology and commitment to quality ensure that we can deliver a massive quantity of high-quality sugarcane seedlings to meet the growing demand for this vital crop.

Why Choose Seedling Planting?

Sugarcane seedling planting offers numerous advantages over traditional methods. By optimizing space utilization and ensuring proper plant density, we can significantly increase the vertical productivity of your sugarcane fields. This approach also reduces production costs, decreases seed usage, and guarantees disease-free, high-quality seedlings. Additionally, our modern irrigation systems and mechanized processes further enhance efficiency and minimize losses during harvesting.

A Strategic Investment for Egypt's Economy

The sugarcane seedling production stations in Kom Ombo and Edfu represent a significant step forward in Egypt's agricultural sector. This initiative not only boosts productivity but also encourages farmers to adopt modern cultivation techniques, contributing to self-sufficiency in sugar. We believe that innovative ideas and visionary approaches are key to unlocking the full potential of this sector.

Partnering with the Ministry of Agriculture

Our certified sugarcane seedling production station is a testament to our collaboration with the Ministry of Agriculture and Land Reclamation. This partnership ensures that our operations adhere to the highest standards of quality and efficiency, benefiting both farmers and the nation.

The Future of Sugarcane Production

By investing in our sugarcane seedling production line, you are not just choosing a product; you are investing in a brighter future for Egyptian agriculture. Our commitment to innovation and sustainability positions us as a leading force in revolutionizing sugarcane cultivation. Let us work together to drive growth and prosperity in this vital sector.

Sugarcane Seedlings Production Line Stages

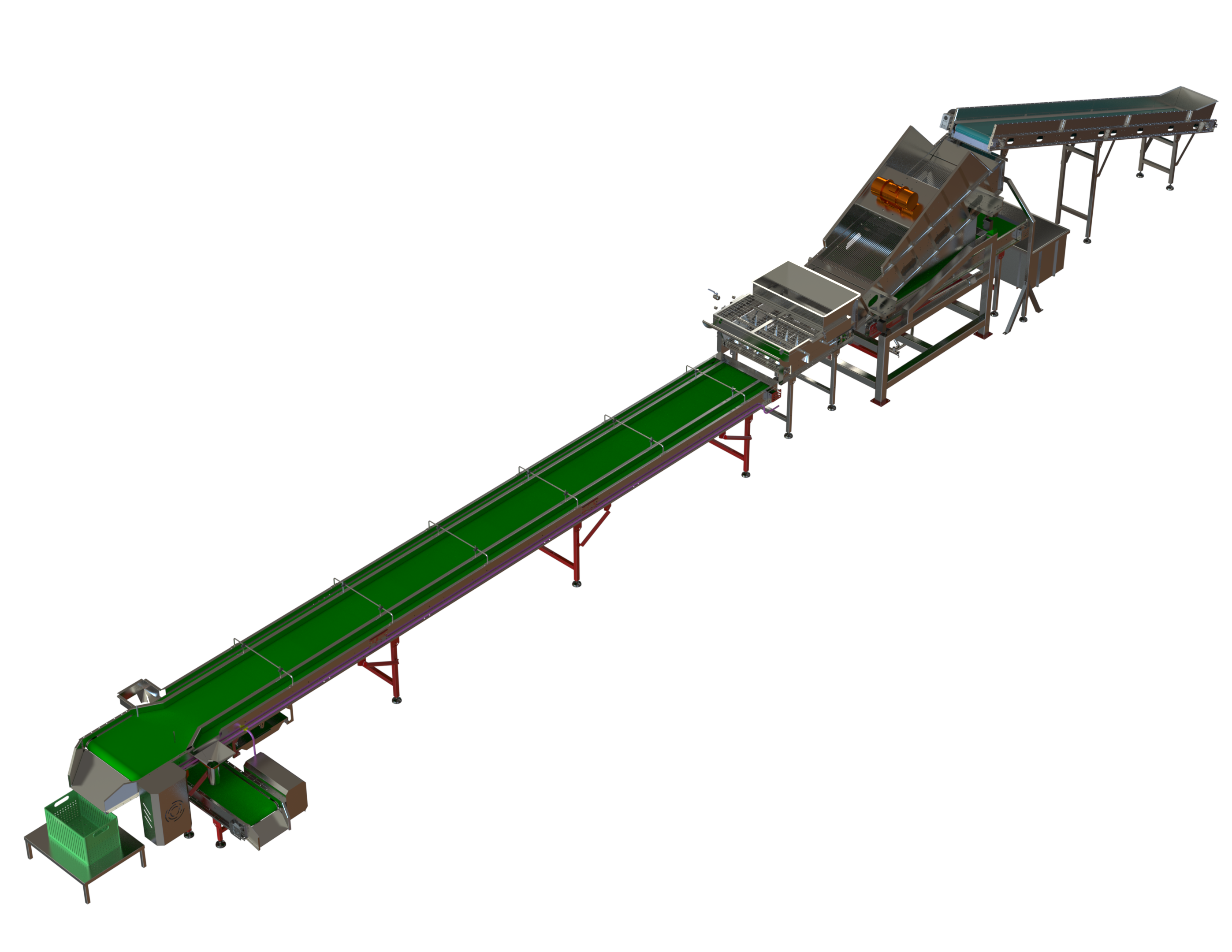

• Preparation and Raw Material Transport Stage

The first crucial step in our sugarcane seedling production process involves the meticulous preparation of the raw material. This stage is executed entirely by skilled workers who are dedicated to ensuring the highest quality of seedlings.

Raw Material Reception and Cleaning:

• Incoming Sugarcane Stalks: We receive freshly harvested sugarcane stalks directly from the fields.

• Manual Cleaning: Our workers meticulously clean the stalks by removing leaves and discarding any undesirable or damaged stalks. This ensures that only the healthiest and most promising material is used for seedling production.

Cutting and Size Reduction:

• Efficient Cutting: To facilitate handling and transportation, we employ two specialized cutters to divide the sugarcane stalks into halves. This reduces the length of the stalks, making them more manageable for subsequent processes.

Transportation to Processing:

• Belt Conveyors: Once cut, the sugarcane stalks are carefully transferred to the processing and mixing station using belt conveyors. This ensures a smooth and efficient flow of raw material throughout the production line.

This initial stage sets the foundation for producing high-quality sugarcane seedlings. By carefully selecting and preparing the raw material, we ensure that our seedlings are healthy, vigorous, and capable of thriving in various field conditions.

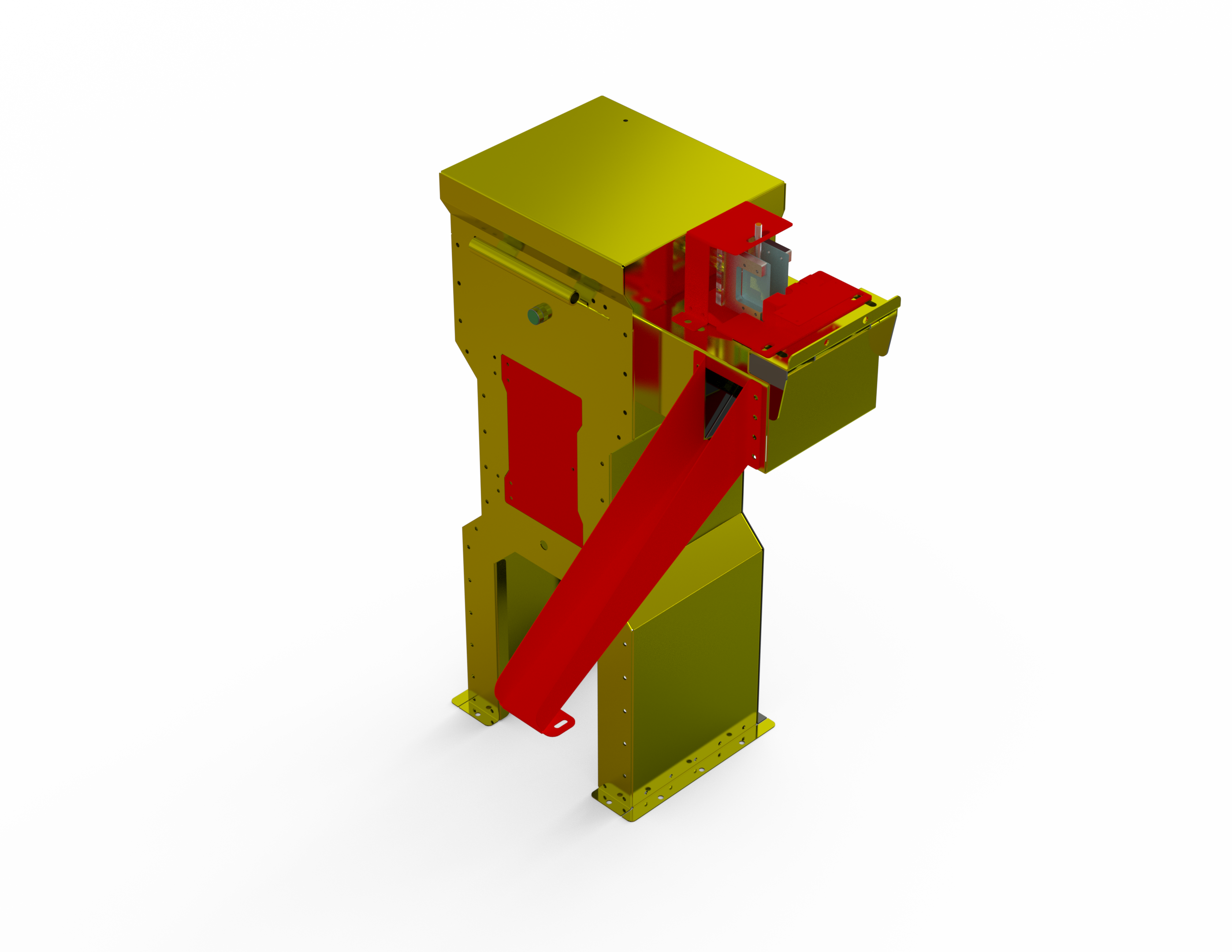

• Bud Cutting Stage:

The bud cutting stage is a critical step in preparing sugarcane stalks for planting as seedlings. This process involves extracting specific segments from the stalks, which contain the buds that will eventually develop into mature plants.

Semi-Automated Cutting Process:

• Specialized Cutters: We employ advanced cutting equipment designed to efficiently extract the desired segments from the sugarcane stalks. This semi-automated process ensures precision and consistency in segment production.

• Segment and Remnant Separation: The cutters separate the segments from the remaining waste material (remnants) of the stalks.

Conveyance and Sorting:

• Multi-Layered Conveyor Belt:

The segments and remnants are transported using a multi-layered conveyor belt. Each layer serves a specific purpose, facilitating the efficient movement and sorting of materials.

• Remnant Removal:

A reverse conveyor system collects the waste remnants and directs them to an upward belt for removal from the station. This stage is essential for producing healthy and productive sugarcane seedlings. By carefully extracting the segments and removing any unwanted material, we maximize the potential of each sugarcane stalk for seedling propagation.

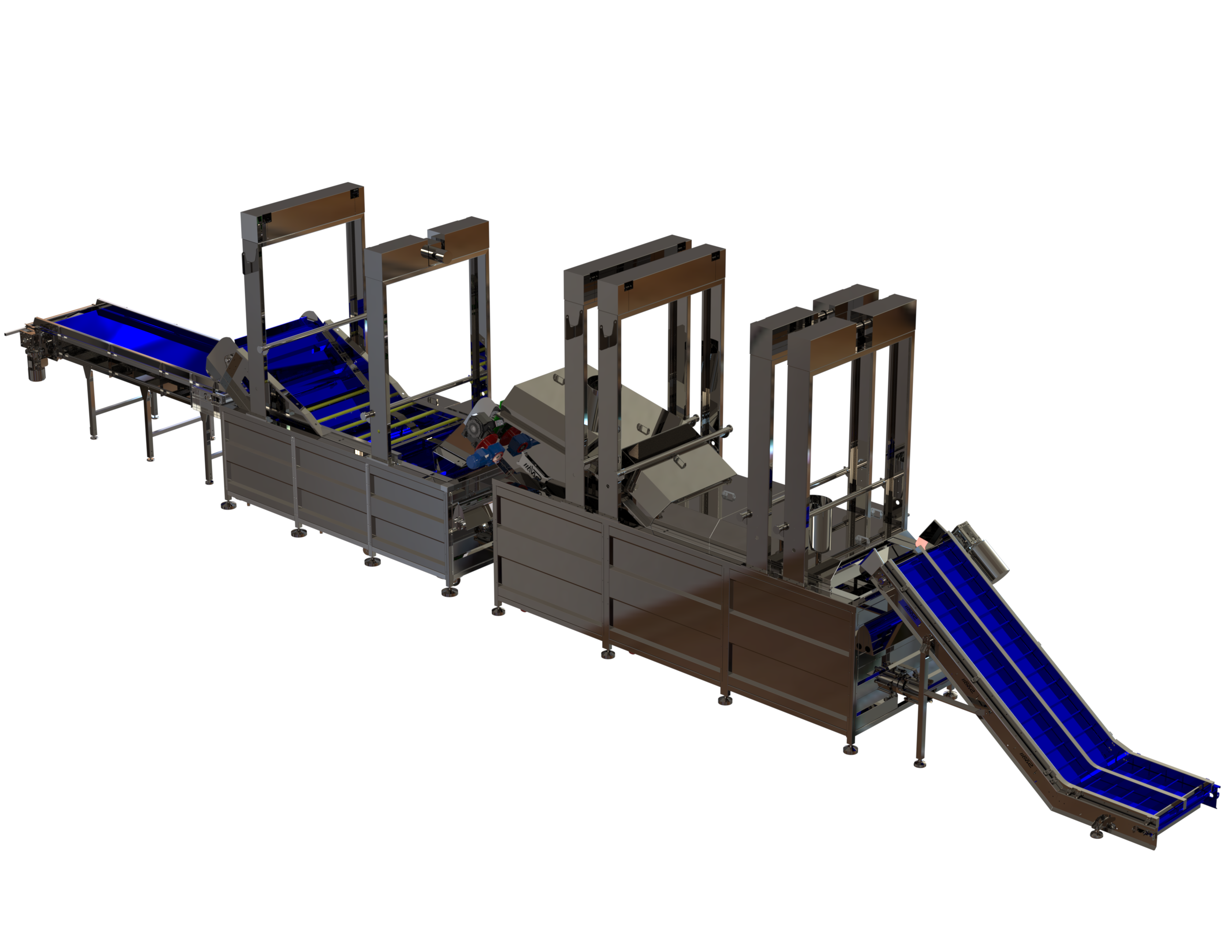

•The Sorting Stage

The sorting stage is a critical step in ensuring the quality of the sugarcane segments. In this process, the segments received from the cutting station are carefully inspected and sorted based on specific criteria. Material Reception and Distribution

• Ascending Conveyors:

The segments are transported from the cutting station to the sorting station via six ascending conveyors. This ensures a steady flow of material for sorting. Manual Sorting

• Sorting Conveyors:

The sorting process is carried out manually on six sorting conveyors. Skilled workers carefully examine each segment, identifying and removing any segments that do not meet the required standards.

Transfer to Processing

• Z-Shaped Conveyors:

After sorting, the selected segments are transferred to the processing station using six ascending conveyors arranged in a Z-shaped configuration. This efficient arrangement facilitates the smooth movement of materials to the next stage.

By meticulously sorting the segments, we eliminate any low-quality or defective material, ensuring that only the best segments proceed to the processing stage. This careful selection contributes to the overall health and vigor of the sugarcane seedlings produced.

• Hot & Chemical Treatment Stage

The processing stage is a crucial step in preparing the sugarcane segments for seedling production. In this station, the segments undergo a combination of thermal and chemical treatments to enhance their quality and promote healthy growth.

Material Reception and Transfer:

• Ascending Conveyors: The segments are received on ascending conveyors to bridge the height difference between the transfer conveyor from the sorting station and the hot treatment conveyors. This ensures a smooth and efficient transfer of materials.

Thermal Treatment:

• Hot Treatment Machine: The segments are subjected to a hot treatment process in a specialized machine. The temperature is maintained at 55°C to eliminate any pathogens or diseases that may be present on the segments.

Chemical Treatment:

• Chemical Treatment Conveyors:

After the thermal treatment, the segments are transferred to chemical treatment conveyors.

• Chemical Treatment Machine:

The segments undergo a chemical treatment process to further protect them from diseases and pests. The specific chemicals used will depend on the prevailing conditions and the desired level of protection.

This processing stage is essential for producing high-quality sugarcane seedlings. The combination of thermal and chemical treatments ensures that the segments are free from harmful pathogens and are well-equipped to develop into healthy and productive plants.

• Mixing and Incubation Stage

A - Bud and Soil Mixing Station

• Primary Mixer:

A primary mixer, such as a peat mixer, is used to prepare the soil for mixing with the buds. This ensures that the soil is adequately prepared to provide the necessary nutrients and support for the seedlings.

• Secondary Mixers:

Additional secondary mixers may be used to further mix the prepared soil with the buds, ensuring a uniform distribution of the buds throughout the soil mixture.

• Pot Filling:

The mixed soil and buds are filled into pots using a conveyor line that transports the pots to the next stage.

B - Incubation Stage:

• Duration: The pots containing the mixed soil and buds are incubated for a period of 7 days. This incubation stage allows the buds to develop and prepare for planting.

C - Bud and Soil Separation Station

• Mechanical Separation:

A mechanical system is employed to separate the buds from the soil after the incubation period. This process ensures that the buds are carefully removed from the soil without damaging them.

• Washing:

The separated buds are washed in a specialized machine to remove any residual soil particles. This cleaning process helps to prevent diseases and ensures that the buds are healthy and ready for planting.

• Sorting and Packing:

The washed buds are carefully sorted and packed, preparing them for planting in the sugarcane fields.

This final step ensures that the seedlings are delivered to farmers in a suitable condition for planting.

This stage is crucial for producing high-quality sugarcane seedlings. The careful mixing of buds and soil, followed by a controlled incubation period, ensures that the seedlings are ready to be planted and thrive in the field. The separation and packing process ensures that the seedlings are delivered in a suitable condition for planting

• Planting Stage

The planting stage marks the final steps in the sugarcane seedling production process. In this station, the buds are carefully planted in plastic trays, preparing them for transfer to pots for further growth.

Automated Planting System:

• Robotic System:

A highly efficient robotic system is used to automate the planting process. This system is capable of planting an impressive 15,000 buds per hour, significantly increasing production capacity and ensuring precision in planting.

Plastic Trays:

• Tray Planting: The buds are planted in specially designed plastic trays, providing a suitable environment for their initial growth. These trays facilitate handling and transportation of the seedlings.

This stage is crucial for ensuring the successful establishment of sugarcane seedlings in the field. The automated planting system guarantees consistent and efficient planting, maximizing the potential for healthy and productive sugarcane crops.

• Packing Stage

The packing stage marks the final step in the sugarcane seedling production process. In this station, the seedlings are carefully prepared for transportation and delivery to farmers.

Automated Removal and Packaging:

• Conveyor Belt:

The seedlings are automatically removed from the trays and placed on a conveyor belt. This efficient process ensures that the seedlings are handled with care and minimizes damage.

• Packaging:

The seedlings are then packaged in appropriate containers, to protect them during transportation and storage.

This final stage is crucial for ensuring that the seedlings are delivered to farmers in a healthy and viable condition. The automated packaging process ensures efficient and safe handling of the seedlings, preserving their quality for planting.