Revolutionize Your Frozen Vegetable Production with Our Cutting-Edge Line

Are you looking to expand your frozen vegetable business with a reliable and efficient production line? Look no further. Our state-of-the-art equipment is designed to streamline your operations, maximize yield, and deliver superior quality products.

With years of experience in the frozen food industry, we have developed a comprehensive range of solutions tailored to meet the specific needs of frozen vegetable producers. From blanching and freezing to packaging and labeling, our line offers a seamless workflow that ensures consistent results.

Discover how our innovative technology can help you:

- Increase production capacity: Our high-speed machines allow you to process larger volumes of vegetables in less time.

- Improve product quality: Our advanced equipment preserves the freshness, flavor, and nutritional value of your vegetables.

- Reduce costs: Our energy-efficient solutions help you minimize operating expenses.

- Enhance food safety: Our hygienic designs and rigorous quality control measures ensure compliance with international standards.

Ready to take your frozen vegetable business to the next level? Contact us today to learn more about our comprehensive production line and how we can help you achieve your goals.

Frozen Vegetables Production Line Steps:

• Material Feeding Stage

Efficient Material Feeding: The Foundation of Our Frozen Vegetable Production Line:

Our state-of-the-art production line incorporates a versatile material feeding system designed to handle a wide variety of vegetables. This three-tiered approach ensures optimal processing for different vegetable types, maximizing yield and preserving quality.

Feeding Line 1:

Catering to delicate vegetables like green peas, beans, and prepared okra, this line incorporates gentle handling techniques to prevent damage and maintain their pristine appearance.

Feeding Line 2:

Designed for root vegetables such as carrots, potatoes, and taro, this line features robust equipment capable of efficiently processing this denser produce.

Feeding Line 3:

Specially engineered for larger, more intricate vegetables like artichokes, whole broccoli, and whole cauliflower, this line utilizes precision feeding mechanisms to ensure accurate handling and prevent breakage.

By tailoring our feeding system to the specific characteristics of each vegetable type, we guarantee efficient processing, minimal waste, and consistent product quality throughout the production line.

• Preparation Stage

Feeding Line 1 (green peas, beans, and prepared okra):

Efficient Processing:Tailoring to the Needs of Each Vegetable Our production line is designed to adapt to the unique characteristics of different vegetable types, ensuring optimal processing at every stage.

For Feeding Line 1, we employ a specialized approach to handle delicate vegetables like green peas, beans, and prepared okra.

Key components in Feeding Line 1:

• Bulk Feeder: This essential equipment ensures a continuous flow of vegetables, maintaining uninterrupted operation and maximizing efficiency.

• Collection Conveyor: Specifically designed for green peas, this conveyor gently collects the vegetables, preserving their quality and preventing damage.

• Elevator: Efficiently transferring peas to the subsequent processing stage, the elevator minimizes handling and reduces the risk of bruising.

.png)

• Air Separators: Removing impurities such as skins, pods, and floaters, these separators ensure a pure and clean product.

• Flotation Washer with Stone Catcher: This innovative machine combines several functions, including washing, flotation, stone removal, and sieving, to thoroughly clean and prepare the vegetables.

• De-Watering Tank / Pump: Recovering and recycling water from the washing process, this system promotes sustainability and reduces water consumption.

• Inspection Conveyor: Providing a final quality check before further processing, this conveyor identifies any defects or imperfections.

• Second Stage Washer: For vegetables other than peas, this washer ensures thorough cleaning and removal of any remaining impurities.

By incorporating these specialized components, we guarantee that delicate vegetables are handled with care, preserving their freshness, flavor, and nutritional value. This attention to detail ensures that our frozen vegetable products meet the highest quality standards.

.png)

Precision Processing of Green Beans: Slicing and Cutting Green beans require specialized processing to prepare them for freezing. Our production line incorporates the following components to ensure efficient and precise slicing and cutting:

• Cluster Cutting: For mechanically harvested green beans, this process separates individual beans from clusters, preparing them for further processing.

• Bean Snipper: This essential equipment removes the tips of the beans, ensuring a uniform appearance and enhancing their culinary appeal.

• Bean Cutter: Designed for automatic slicing of whole green beans, this machine offers two cutting options: o 35 mm: For shorter, more bite-sized pieces. o 25 mm: For a finer, more delicate cut. The bean cutter incorporates a vibration feeding system to straighten the beans before cutting, ensuring accurate and consistent results. Additionally, the machine features a hopper to collect the cut beans and direct them to the conveyor, minimizing waste and maximizing efficiency.

With a defect rate of less than 10%, our green bean processing line delivers high-quality, uniform products that meet the most demanding standards.

Feeding Line 2 (Root Vegetables)

Efficient Processing of Root Vegetables: From Feeding to Slicing

Feeding Line 2 is designed to handle root vegetables such as carrots, potatoes, and taro. This line incorporates specialized equipment to ensure efficient processing, minimize waste, and deliver high-quality products.

Key components in Feeding Line 2:

• Feeder System: This system receives the vegetables from the source, buffers them, and elevates them to the subsequent processing stage.

• Sand Remover: Gently removing sand, soil, and insects, this equipment ensures a clean and hygienic product.

• Drum Washer: Thoroughly washing the root vegetables, this machine removes dirt and impurities

• Stone Trap: Automatically separating natural stones from the product, this device prevents damage to the processing equipment and ensures product safety.

• Peeler: Offering precise and controlled peeling, this peeler minimizes waste and maintains the desired shape of the vegetables.

• Inspection Station: Equipped with multiple working stations, this conveyor allows for thorough visual inspection of the peeled vegetables.

• Carrot/Potato Slicer/Dicer: This machine offers automatic cross-cutting and crinkle-shape cutting of carrots and potatoes, ensuring a consistent and uniform product. The slicer/dicer is capable of producing various diced sizes to meet specific customer requirements.

With a defect rate of less than 5%, our root vegetable processing line delivers high-quality, precisely cut products that are ideal for a wide range of applications.

Feeding Line 3 (Broccoli, cauliflower)

Preparing Broccoli and Cauliflower:

A Manual Process with Modern Tools Feeding Line 3 is designed to handle whole broccoli and cauliflower, which are received at the factory and undergo a manual preparation process before freezing.

Key components in Feeding Line 3:

• Feeder: This equipment receives the vegetables and transfers them to the subsequent processing stage.

• Washer: Thoroughly cleaning the broccoli and cauliflower, this machine removes dirt and impurities.

• Manual Inspection Station: Here, the vegetables are visually inspected by the production team to ensure they meet quality standards. The preparation process for broccoli and cauliflower typically involves cutting them into smaller pieces, often between 25 and 35 millimeters, to meet specific product specifications.

This process is often carried out manually using specialized knives and measuring tools.

• Blanching Stage

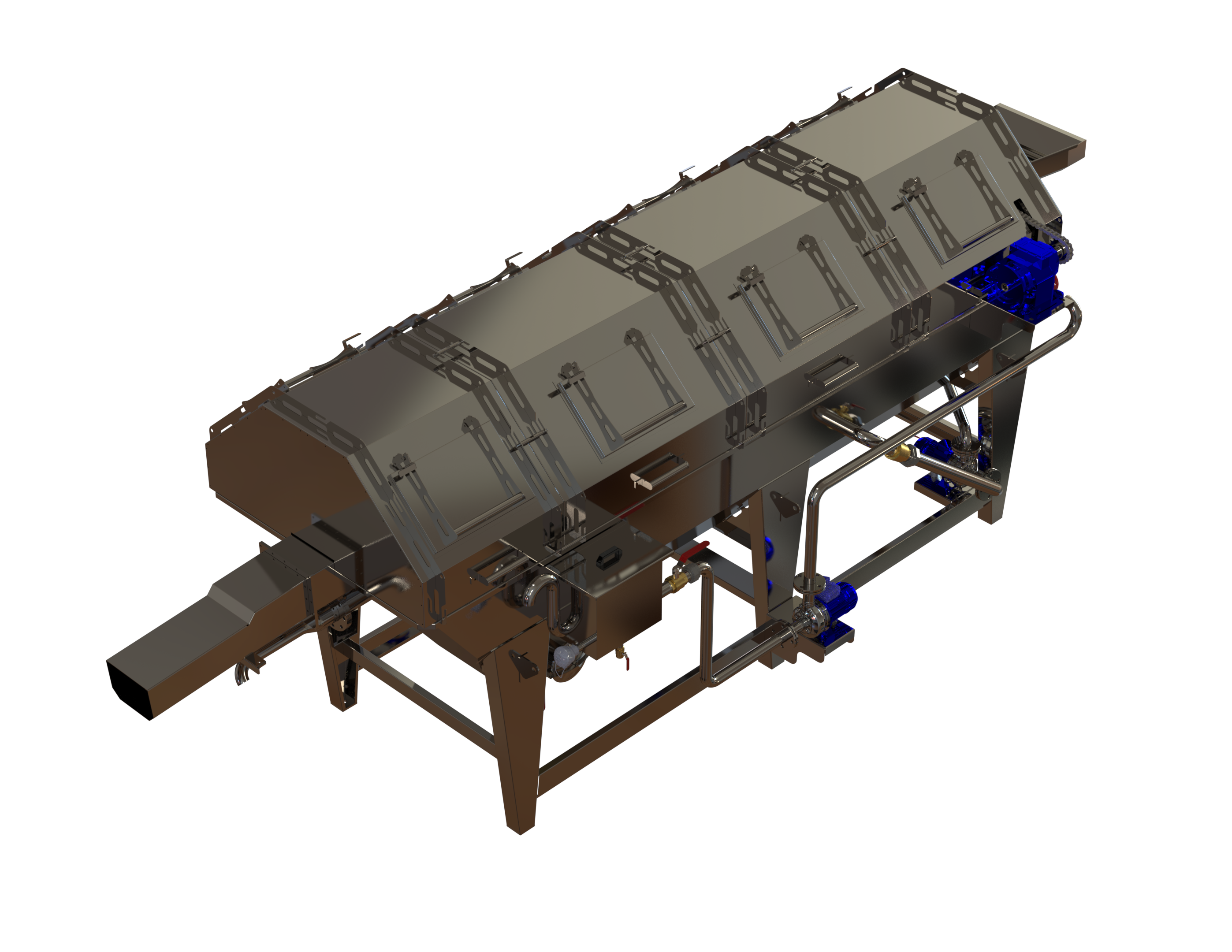

Blanching: Preserving Freshness and Quality:

The blanching stage is a critical step in the frozen vegetable production process. It involves immersing the vegetables in hot water for a specific period to deactivate enzymes, preserve color, and prepare them for freezing. Our state-of-the-art blancher-cooler is designed to optimize this process for a variety of vegetables.

Key features of our blancher-cooler:

• Modular Design: This flexibility allows us to adapt the machine to different vegetable types and production requirements.

• Uniform Feeding: Ensuring even blanching and consistent quality throughout the batch.

• Efficient Water and Steam Consumption: Minimizing operating costs and promoting sustainability.

• Automatic Cleaning System (CIP): Streamlining maintenance and ensuring hygienic production.

• Precise Control: Accurate control of process temperature, media consumption, and other critical parameters.

Blanching Process Specifications:

• Capacity: Based on green peas, the machine can handle a specified volume of product.

• Blanching Time: Adjustable from 30 seconds to 25 minutes, depending on the vegetable type and desired outcome.

• CIP System: Included for thorough cleaning in place.

• Product Cooling: Cooling the vegetables to 10±20°C after blanching.

• Cold Water: Supplied by a falling heat exchanger using water or ammonia.

• Heating Temperature: Adjustable up to 96°C.

• pH Dosing System: Included for precise pH adjustment.

• No Steam Leakage: Preventing contamination and ensuring product safety.

In addition to the blancher-cooler, our system includes:

• CIP System for Blancher: A separate CIP system specifically designed for cleaning the blancher.

• Separate Chiller: Cooling, filtering, and recirculating process water for optimal performance.

• Collection/Dewatering Station: Gently collecting and dewatering the blanched vegetables, preparing them for the next stage.

By incorporating these advanced technologies, we ensure that our blanching process is efficient, effective, and produces high-quality frozen vegetables.

.png)

• IQF Stage

Lock in Freshness: The Crucial IQF Stage:

The heart of our frozen vegetable production process is the IQF (Individually Quick Frozen) stage. This critical step is paramount in preserving the exceptional quality of our vegetables. Unlike traditional methods, our IQF technology eliminates the need for mechanical components, gently carrying and separating each vegetable individually as it freezes. This rapid freezing process prevents the formation of damaging ice crystals, safeguarding the vegetables' original texture, flavor, and appearance.

.png)

• Packing Stage

Packaging: The Final Step in Preserving Freshness:

After passing through the IQF stage, the frozen vegetables are carefully weighed and bulk-packaged for storage and distribution. These bulk packages are then moved to the packing station, where they undergo retail packaging. Our retail packaging process involves portioning the frozen vegetables into convenient bags, typically weighing around 400 grams each. These bags are designed to be consumer-friendly, featuring clear labeling that provides essential product information such as weight, ingredients, and nutritional content. By utilizing efficient packaging methods, we ensure that our frozen vegetables reach consumers in pristine condition, maintaining their freshness, quality, and nutritional value.