Unlock the Potential of Egypt's Golden Harvest with our Citrus Processing Line:

· Egypt, renowned for its rich agricultural heritage, stands as a global leader in citrus production. This vibrant industry offers unparalleled opportunities for businesses seeking to capitalize on the worldwide demand for fresh, high-quality citrus fruits.

· Our expertise lies in transforming this natural abundance into a profitable venture. Through years of meticulous research and development, we have engineered the ultimate citrus sorting and packing line. This state-of-the-art solution is meticulously designed to align seamlessly with your specific market needs, ensuring your products stand out on shelves worldwide.

· Let's embark on a journey to discover how our cutting-edge technology can elevate your citrus business and tap into the immense potential of Egypt's golden harvest.

Citrus Processing Steps:

• Material Feeding

High-Speed Precision Feeding:

Our citrus processing journey commences with a robust foundation: our high-capacity mechanical dumper. This industrial powerhouse efficiently handles a staggering 1300-1400 boxes per hour, ensuring a consistent and uninterrupted flow of citrus fruits into the processing line. This impressive throughput sets the stage for maximum productivity and optimal output.

• Initial Sorting

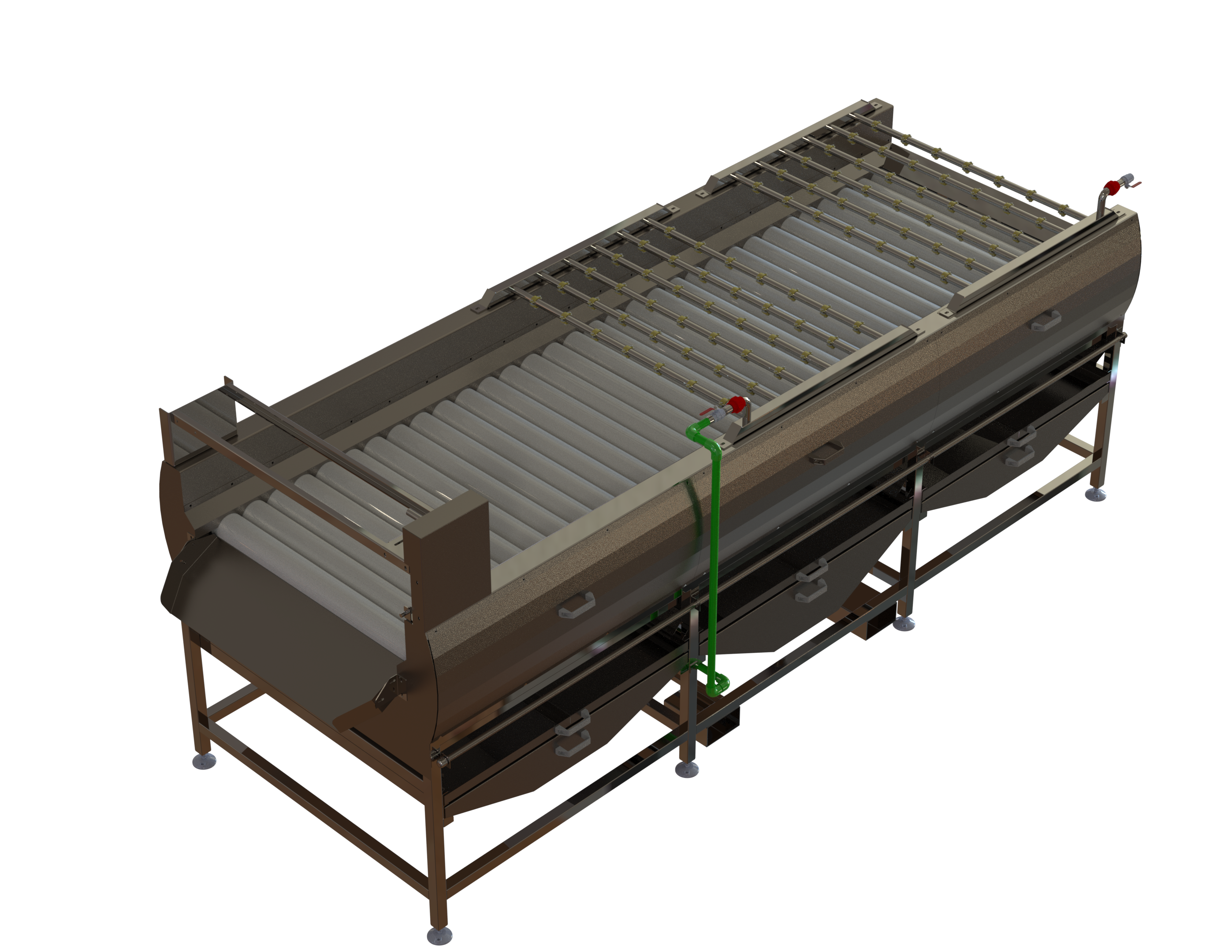

Precision Quality Control:

Maintaining the highest quality standards is paramount. Our citrus fruits undergo a meticulous initial sorting process on a specialized sorting conveyor equipped with rollers, a belt conveyor, and overhead lighting. Here, trained professionals diligently inspect each fruit, swiftly removing any rotten or damaged specimens. This critical step is essential for preventing contamination and ensuring the integrity of the entire processing line. By eliminating substandard fruits at this early stage, we guarantee that only the finest citrus continues its journey towards perfection.

• Washing

Deep Cleansing for Optimal Purity:

To ensure impeccable hygiene and product quality, our citrus fruits undergo a rigorous washing process. Our state-of-the-art washing and brushing machine employs high-pressure water sprays and specialized brushes to effectively remove dirt, pesticides, and any remaining impurities.

A cutting-edge foam generator system further enhances the cleaning process, leaving your citrus fruits spotless and ready for the next stage. This meticulous cleansing step is crucial for meeting the most stringent food safety and quality standards.

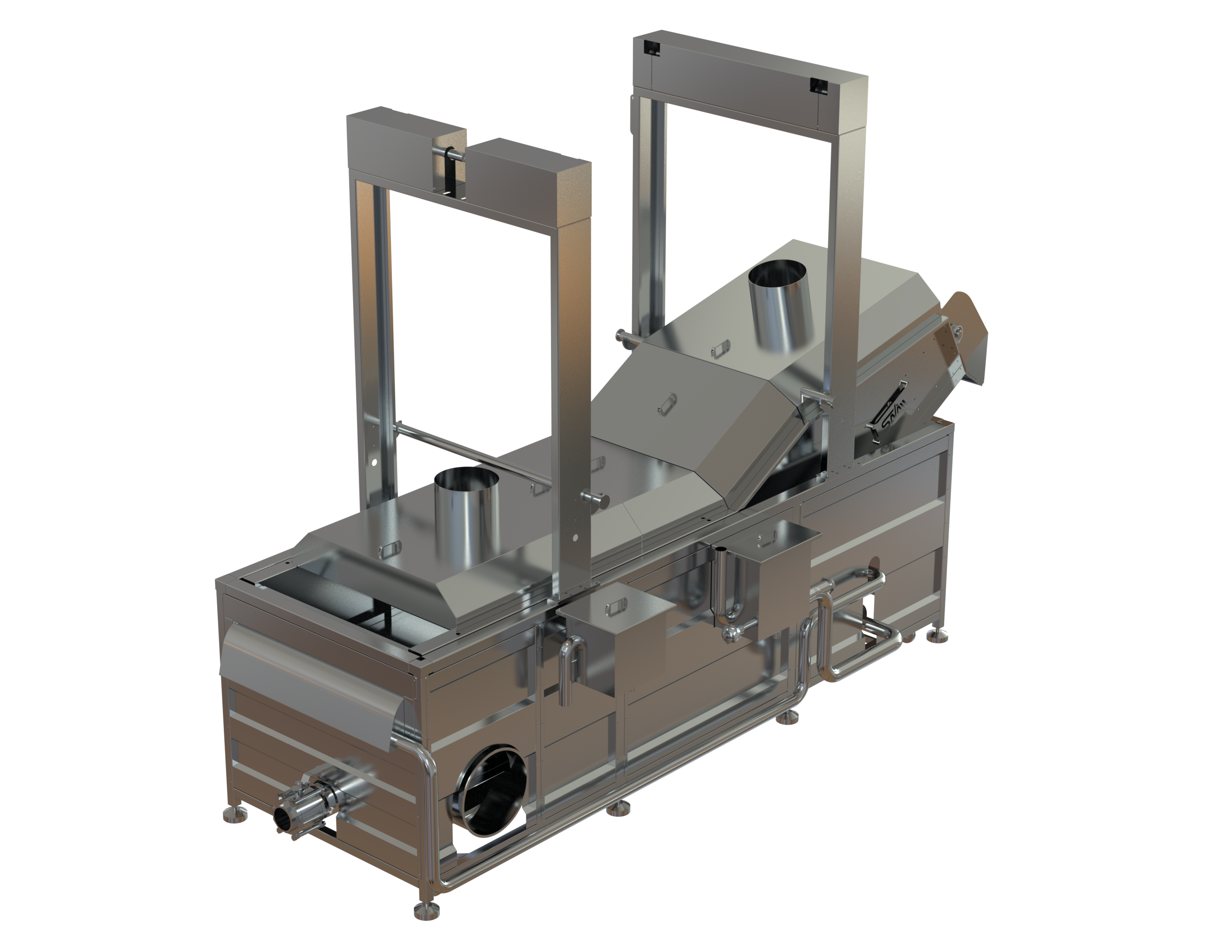

• Hot Treatment

Prolonging Freshness: Thermal Processing:

To guarantee optimal food safety and product longevity, our citrus fruits undergo a critical hot water treatment process. Immersed in a specialized stainless steel tank, the fruits are subjected to precise temperature control, ensuring effective elimination of harmful microorganisms. Our advanced system features a burner, pump, and a sophisticated electrical panel that manages temperature, submerger movement, and overall tank operation. This meticulous process fortifies the fruit's natural defenses while maintaining its freshness and flavor.

• Initial Drying

Precision Drying for Optimal Waxing:

Our advanced drying tunnel plays a pivotal role in preparing your citrus fruits for the subsequent waxing process. Following the hot water treatment, the fruits enter this carefully engineered environment where excess moisture is efficiently removed.Our drying tunnel incorporates aluminum rollers for gentle fruit handling. A powerful hot air generator, complete with an automatic burner, heat exchanger, and insulated conduction pipes, ensures optimal drying conditions. The stainless-steel construction of fruit-contacting surfaces guarantees hygiene and durability. Advanced features such as a geared motor with speed inverter, automatic roller cleaning systems, and a precise hot air distribution system enhance efficiency and product quality. The electrical panel, equipped with a digital thermostat, provides precise temperature control for consistent results. By meticulously removing moisture, this stage creates the perfect foundation for the next step: waxing.

• Pre-Waxing Sorting

Meticulous Pre-Waxing Sorting:

To ensure an impeccable final product, our citrus fruits undergo a second, crucial sorting phase before the waxing process. This stage is essential for identifying and removing any fruits that may have sustained damage during the initial drying process or those that simply do not meet our stringent quality standards. Our sorting conveyor is designed for maximum efficiency and precision. Equipped with a geared motor and speed inverter for customizable operation, this sorting station allows for thorough inspection of each fruit. The stainless-steel construction of fruit-contacting surfaces maintains hygiene, while the integrated lighting system ensures optimal visibility. By meticulously examining each fruit at this stage, we guarantee that only the very best citrus proceeds to the waxing phase.

• Waxing

Imparting Perfection: The Waxing Process:

Our state-of-the-art waxing machine is the final step in elevating your citrus fruits to premium status. This advanced equipment utilizes a combination of rotating spray systems with precise pressure regulation and high-performance brushes to apply a flawless wax coating.

The benefits of this meticulous process are undeniable:

• Optimal Preservation:

The wax coating effectively controls shrinkage, extending shelf life and ensuring your citrus fruits reach consumers at peak freshness.

• Enhanced Market Appeal:

The imparted shine significantly enhances the fruit's visual appeal, making it more attractive to consumers and commanding a premium price.

• Moisture Retention:

By creating a protective barrier, the wax coating minimizes weight loss and dehydration, safeguarding the fruit's quality. Our waxing process is the culmination of our commitment to delivering exceptional citrus products.

• The Final Drying (Post-Waxing Drying)

The Final Polish: Post-Waxing Drying:

To achieve the perfect finish, our citrus fruits undergo a final drying process after the waxing stage. This crucial step ensures that the wax coating is fully set and any residual moisture is eliminated. Our drying tunnel employs aluminum rollers for gentle fruit handling. A powerful hot air generator, equipped with an automatic burner, heat exchanger, and insulated conduction pipes, provides precise temperature and humidity control. The hot air is evenly distributed throughout the tunnel, optimizing the drying process. By completing this final stage, your citrus fruits emerge with a flawless appearance, extended shelf life, and optimal product quality.

• Optical Sorting & Grading

Before the final packaging stage, our citrus fruits undergo a meticulous optical sorting and grading process, powered by A cutting-edge sorting machine. This innovative technology employs advanced vision systems to detect even the most subtle external defects, such as bruises, blemishes, blackspots, scars, and more, with unparalleled accuracy. Beyond external defects, this sorting machine's non-invasive technology penetrates the sub-surface of the citrus, analyzing critical factors like brix content, acidity, ripeness, and frost damage. This comprehensive analysis ensures that only the highest quality fruits proceed to the packaging stage.

How it Works:

• Singulation and Transportation:

Citrus fruits are individually separated and transported to the sorting machine using specialized roller cups.

• Rotation and Imaging:

The roller cups gently rotate each fruit as it passes beneath high-resolution and infrared cameras.

• Image Analysis:

Our innovative vision software meticulously analyzes the captured images, precisely characterizing each product based on various parameters, including weight, size, shape, color, ripeness, brix content, acidity, external quality, and internal quality.

By incorporating optical sorting and grading into our process, we elevate our citrus products to new heights of perfection, ensuring that only the finest specimens reach consumers.

• Packing

The Final Touch:

The culmination of our citrus processing journey is the meticulous packing process. Our packing tables, each spanning an impressive 20 meters, are the stage for transforming individual fruits into marketable products. Citrus fruits that have successfully navigated the rigorous sorting and quality inspection process are carefully arranged by skilled packers. Based on predefined parameters for size, color, and quality, workers diligently select fruits that meet the highest standards. These perfect specimens are then expertly packed into cartons, trays, or crates, ready to captivate consumers. This final stage is a testament to our commitment to delivering citrus products of unparalleled quality and presentation.