Introduction: A Fresh Start for Egypt's Potato Industry

Introduction: A Fresh Start for Egypt's Potato Industry

Are you looking to capitalize on Egypt's booming potato export market? Look no further. Our state-of-the-art potato processing and packing line offers a unique opportunity to streamline your operations and increase your export revenue.

As the second largest agricultural export in Egypt, potatoes have immense potential for growth. With our advanced technology and efficient processes, we've designed a line that can transform your potatoes into high-quality value-added and marketable products that meet the stringent demands of international markets.

Why choose our processing and packing line?

Cutting-Edge Technology: Our line is equipped with the latest advancements in processing machinery, guaranteeing efficiency, precision, and optimal product quality.

Efficiency: Our streamlined processes reduce labor costs and maximize output.

Quality: Our equipment ensures that your potatoes are processed and packed to the highest standards.

Customization: We understand that every business has unique requirements. Our team works closely with you to tailor the line to your specific needs and goals.

Profitability: By increasing your export volume and improving product quality, you can significantly boost your profits, as Investing in our potato processing line offers a significant return on investment. By producing high-quality products, you can increase market share and command premium prices.

Sustainability: Our processes prioritize sustainability, minimizing waste and environmental impact.

Ready to learn more? In the following sections, we will guide you through the exciting journey of your potatoes, from harvest to export. Discover how our innovative line can help you achieve your business goals and secure a thriving future in the potato industry.

Fresh Potato Process Line Stages

• Material Infeed

Potato Reception and Distribution:

Our process begins with the efficient handling of incoming potato shipments. A specialized tipping mechanism carefully unloads boxes of potatoes onto a receiving hopper. This hopper acts as a buffer, collecting the potatoes and ensuring a steady flow to the subsequent processing stages. The system is designed to distribute the potatoes evenly, preventing bottlenecks and optimizing production efficiency. Operators can easily control the rate at which potatoes are fed into the line, ensuring a smooth and uninterrupted process. This robust and reliable infeed system accommodates various potato varieties and quantities, providing a seamless start to the processing journey.

• De-stoning

Removing Contaminants from Potatoes:

To ensure the highest quality and safety of our potato products, we employ a sophisticated destoning machine. This equipment effectively removes stones, dirt, twigs, and other foreign matter that may be present in the potatoes prior to the washing process. By eliminating these contaminants, we safeguard the integrity of the product and prevent potential damage to downstream machinery. This essential step is crucial for producing clean and wholesome potatoes that meet the highest standards of excellence.

• Washing

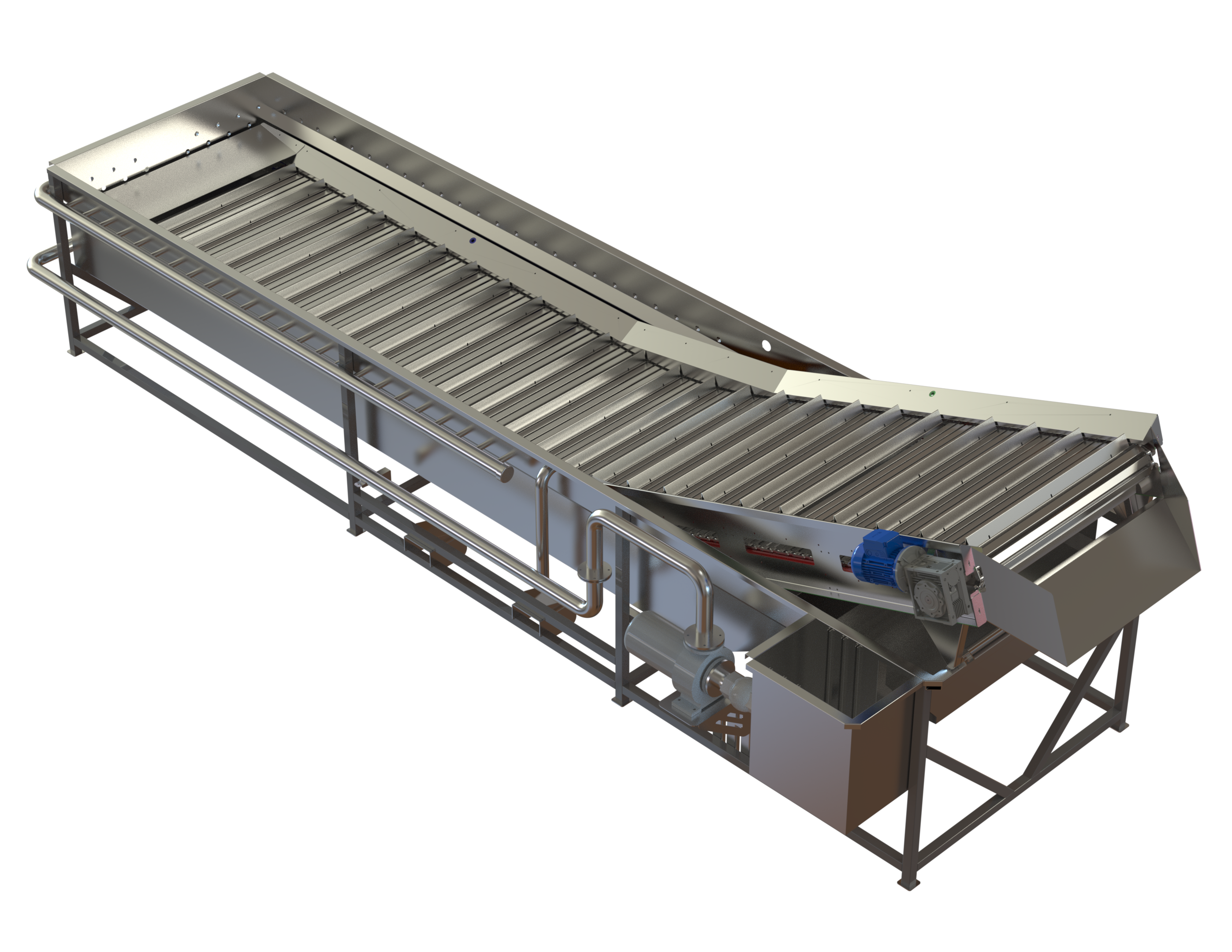

1. Pre-soaking

A Gentle Cleanse for Fresh Potatoes:

Our presoaking system is a cost-effective and versatile solution designed to gently remove excess soil and debris from potatoes before the main washing process. Using a combination of air agitation and microbubbles, this system effectively loosens dirt and contaminants without damaging the delicate potato skin.

Key benefits of our presoaking system include:

• Gentle Cleaning: The system's gentle approach ensures that potatoes are thoroughly cleaned without any bruising or damage.

• Versatility: Suitable for both dirty and clean potatoes, this system can be adapted to various incoming produce conditions.

• Cost-Effective: Our presoaking solution offers a cost-effective way to improve the quality and cleanliness of your potatoes.

• Durability: Available in mild and stainless-steel construction, the system is built to last and withstand the demands of high-throughput processing.

By incorporating this presoaking stage into your potato processing line, you can enhance the overall quality of your product and optimize your production efficiency.

2. Drum washing

A Deep Clean for Pristine Potatoes:

Our drum washer is a cutting-edge solution for thoroughly cleaning potatoes. Equipped with the latest technology, this machine offers exceptional cleaning power while minimizing water consumption. The robust construction features a perforated drum shell and a stainless-steel infeed to prevent soil buildup.

Key benefits of our drum washer include:

• Efficient Cleaning: The rotating drum and water spray system ensure thorough removal of dirt and mud.

• Water Conservation: Our smart dirt removal system allows for operation with significantly reduced water consumption.

• Durable Construction: The solid and heavy-duty design ensures long-term reliability.

• Easy Operation: The synchronized motor and VDF control system provide smooth operation and easy restart after emergencies.

By investing in our drum washer, you can achieve exceptional potato cleanliness while optimizing your water usage and production efficiency.

• Polishing

A Finishing Touch for Premium Potatoes:

Our polishing machine adds the final touch to your potatoes, transforming them into premium-quality products. Equipped with specialized brushes, this machine gently removes any remaining residues from the potato surface, revealing a smooth and radiant finish. This polished appearance is highly appealing to consumers, making your potatoes stand out in the marketplace.

Investing in a polishing machine offers several key advantages:

• Enhanced Appearance: Polished potatoes have a more attractive and premium look, capturing the attention of discerning buyers.

• Longer Shelf Life: The polishing process helps to remove imperfections and extend the shelf life of your potatoes.

• Added Value: Offering premium-quality potatoes can differentiate your products from competitors and increase their perceived value.

By incorporating a polishing stage into your processing line, you can elevate your potatoes to a new level of excellence and attract a wider customer base.

• Drying

Removing Excess Moisture:

Our potato drying machine utilizes a series of sponge-like rollers to effectively remove excess moisture from the potatoes. As the potatoes pass through the machine, the rollers absorb water, ensuring a dry and finished product. This drying stage is crucial for preparing potatoes for packaging and storage, preventing spoilage and maintaining optimal quality.

Key features of our potato drying machine include:

• Efficient Drying: The sponge-like rollers effectively absorb water from the potato surface.

• Gentle Handling: The rollers gently rotate to ensure even drying without damaging the potatoes.

• Durable Construction: Available in mild or stainless steel, the machine is built to last and meet food safety standards.

• Versatility: Suitable for drying potatoes after washing or polishing, this machine can be integrated into various processing lines.

By incorporating a drying stage into your potato processing line, you can ensure that your products are dry, fresh, and ready for market.

• Sorting

A Final Quality Check

Our belt inspection conveyor is specifically designed for the manual sorting of potatoes. This conveyor system provides a clear and well-lit workspace for operators to carefully inspect each potato, ensuring only the highest quality products are selected.

Key features of our belt inspection conveyor include:

• Visibility: The blue PVC belt provides excellent contrast against the potatoes, making it easy to identify defects or imperfections.

• Lighting: The conveyor is equipped with fluorescent or LED lighting to ensure optimal visibility during inspection.

• Efficiency: The belt conveyor efficiently moves the potatoes along for a thorough and timely inspection.

By incorporating a manual sorting stage using our belt inspection conveyor, you can maintain strict quality control and deliver only the finest potatoes to your customers.

• Grading

There are 2 types of grading:

Our potato grading system offers two effective methods for sorting potatoes based on size: shake grading and radial grading.

Shake Grading:

• Precision Sizing: The shake grader accurately sorts potatoes by their square size in four dimensions, ensuring precise classification.

• Multi-Level Sieves: The machine features multiple levels of sieves with progressively smaller openings, allowing potatoes to fall through based on their size.

• Vibration-Based Sorting: The sieves are agitated using motors, causing the potatoes to shake and move through the appropriate openings.

Radial Grading:

• Diameter-Based Sorting: The radial grader sorts potatoes based on their diameter.

• Adjustable Grading: The gap between the stainless-steel rollers can be adjusted to achieve the desired grading sizes.

• Efficient Sorting: Potatoes are fed onto the rollers and fall through the gaps based on their size, allowing for efficient separation.

By incorporating either or both of these grading methods into your processing line, you can accurately sort potatoes into different size categories, meeting the specific needs of your target market.

• Packing

Preparing Potatoes for Market:

The final stage of our potato processing line involves packaging the products for distribution. We offer two packaging options to suit your needs:

Retail Packaging:

• Net Bagging: Our net bagging machine is ideal for packaging smaller to medium-sized potatoes in branded net bags. This attractive packaging option is perfect for retail sale, enticing consumers at the supermarket.

• Weight Consistency: The potatoes are weighed automatically before being placed in the net bags, ensuring each bag has a consistent weight and uniform potato size.

Bulk Packaging:

• Box and Bag Filling: For larger quantities of potatoes, we offer box and bag filling machines. These machines carefully pack potatoes layer by layer into boxes or bags without damaging them.

• Strategic Placement: The machines are strategically located along the processing line to ensure that potatoes of the same size are packed together.

By choosing the appropriate packaging method, you can effectively prepare your potatoes for distribution and maximize their appeal to customers.